Damage calculation on an economic level

Are you an existing customer or do you want to contact us in a different matter? We look forward to hearing from you and will get back to you as soon as possible.

Alternatively, you may want to contact directly one of our locations or our holding company.

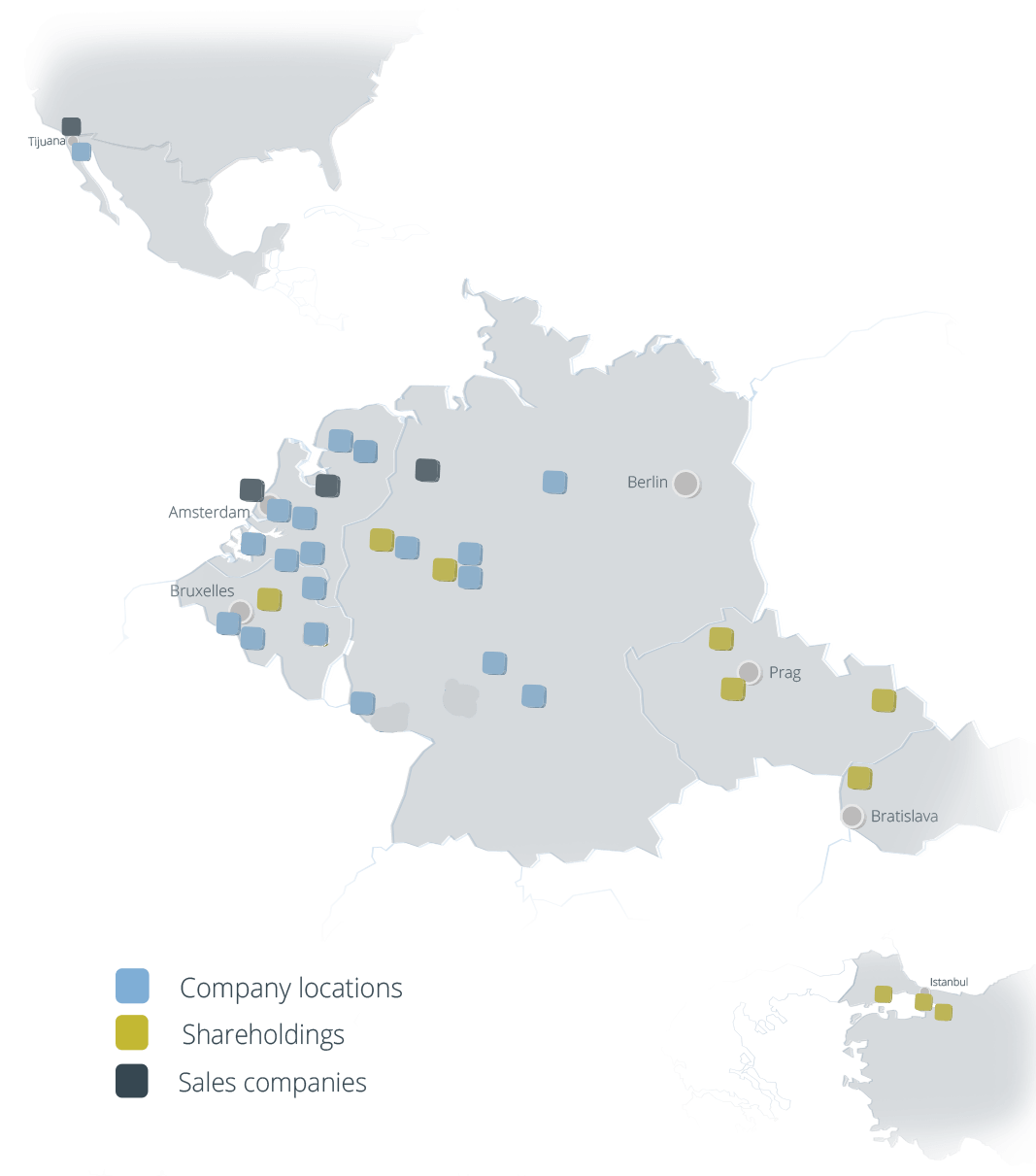

Locations

The Coatinc-Network

Slovakia

Netherlands

- Alblasserdam / NL

alblasserdam@coatinc.com - Amsterdam / NL

amsterdam@coatinc.com - Barneveld / NL

nederland@coatinc.com - De Meern / NL

demeern@coatinc.com - Groningen / NL

groningen@coatinc.com - Groningen – Pulverbeschichtung / NL

cgr.verkoop@coatinc.com - Mook / NL

mook@coatinc.com - Mook – PreGa / NL

prega.nl@coatinc.com - Roermond / NL

roermond@coatinc.com - Scherpenzeel / NL

anox@coatinc.com

For enquiries regarding marketing or press matters, please use the following contacts:

Marketing & Press

The Coatinc Company Holding GmbH

Hüttenstraße 45

57223 Kreuztal

Your contact person:

Anna-Maria Ademaj

marketing@coatinc.com

Holding

Headquarter

The Coatinc Company Holding GmbH

Carolinenglückstraße 6-10

44793 Bochum, Germany

Phone: +49 234 52905-0

Fax: +49 234 52905-15

Encyclopedia

Damage calculation on an economic level

Damage calculation on an economic level

Current studies by the World Corrosion Organisation (WCO) demonstrate the necessity of checking for corrosion. This is important because corrosion is normally only the focus of attention when spectacular cases of damage occur. But corrosion with its causes and consequences is an everyday phenomenon – and a permanent risk.

The economic damage caused by corrosion in industrialised countries reaches up to a two-digit percentage of the gross domestic product, globally the rate lies by around 3 % of the gross national product. Corrosion puts both industrial and emerging countries at risk in the same way – it reduces the quality of life, puts public safety at risk and, in the worst case, can be the cause of damage to the environment and health (stress due to the release of heavy metals). The public infrastructure is also affected: clear signs are, for example the significant increase in the restoration of steel reinforcements which are damaged by external influences such as air and water contamination, different organic and non-organic compounds and microbiological processes.

Corrosion causes manifold costs. Not only the materials (steel, concrete, etc.) need to be replaced at high costs, the necessary working hours for the repair of objects also need to be taken into account. We differentiate between direct and indirect corrosion damage costs:

Direct corrosion damage costs:

- working hours for the project planning of objects with suitable corrosion protection,

- expenses for aggregates which, for example, protect the concrete from chemical influences,

- expenses for coatings which offer protection from corrosion,

- reduction of the steel’s firmness (static deficiencies).

Indirect corrosion damage costs:

- production downtimes caused by corrosion damage which lead to malfunctions, damages or even the plant being shut down while being repaired,

- other costs which occur when an object is blocked, for example fuel costs which occur due to diversions caused by a blocked bridge,

- fluids which are lost from containers and pipelines due to corrosive cracks,

- thermal loss.