Zinc flake process

Are you an existing customer or do you want to contact us in a different matter? We look forward to hearing from you and will get back to you as soon as possible.

Alternatively, you may want to contact directly one of our locations or our holding company.

Locations

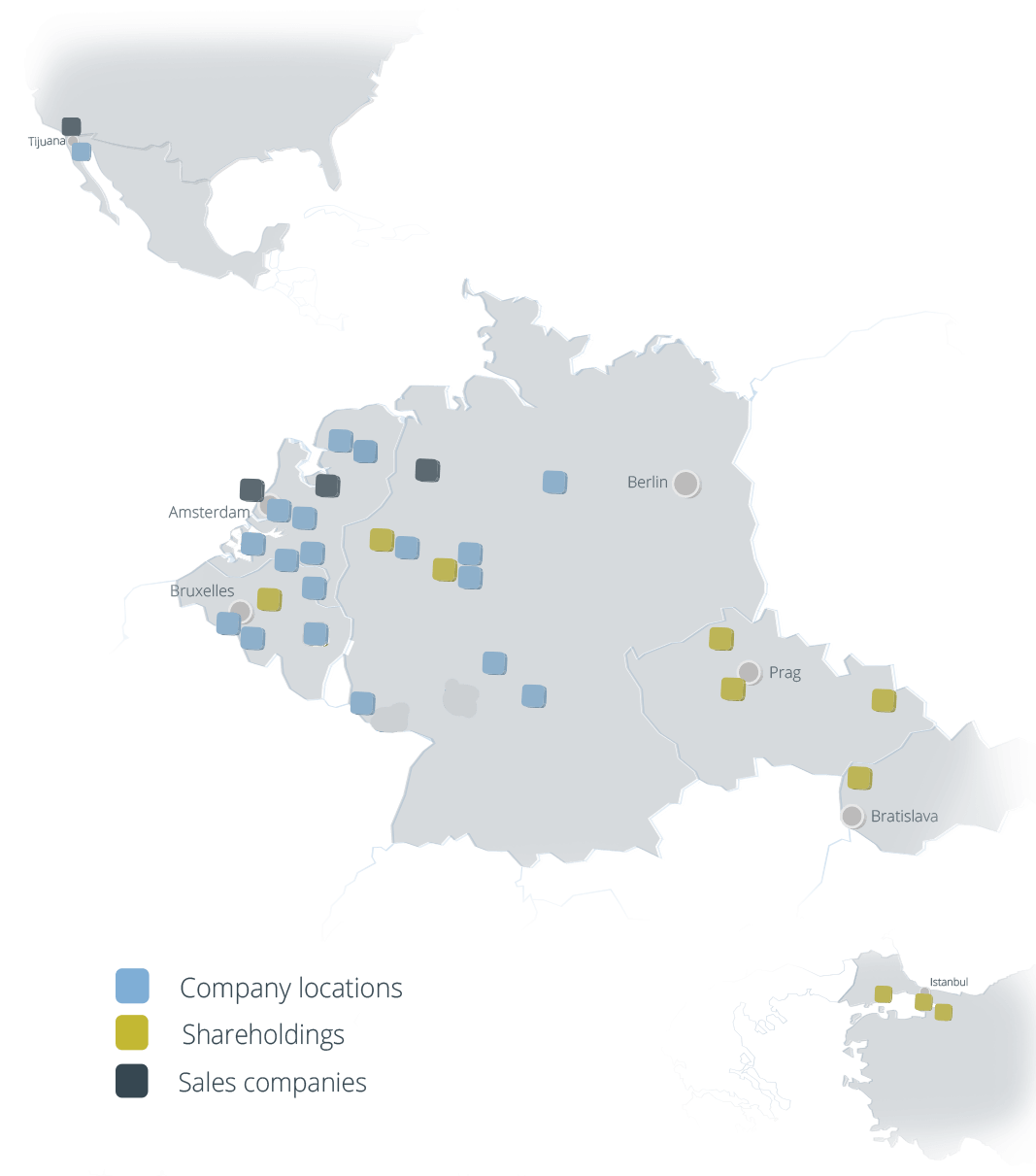

The Coatinc-Network

Slovakia

Netherlands

- Alblasserdam / NL

alblasserdam@coatinc.com - Amsterdam / NL

amsterdam@coatinc.com - Barneveld / NL

nederland@coatinc.com - De Meern / NL

demeern@coatinc.com - Groningen / NL

groningen@coatinc.com - Groningen – Pulverbeschichtung / NL

cgr.verkoop@coatinc.com - Mook / NL

mook@coatinc.com - Mook – PreGa / NL

prega.nl@coatinc.com - Roermond / NL

roermond@coatinc.com - Scherpenzeel / NL

anox@coatinc.com

For enquiries regarding marketing or press matters, please use the following contacts:

Marketing & Press

The Coatinc Company Holding GmbH

Hüttenstraße 45

57223 Kreuztal

Your contact person:

Anna-Maria Ademaj

marketing@coatinc.com

Holding

Headquarter

The Coatinc Company Holding GmbH

Carolinenglückstraße 6-10

44793 Bochum, Germany

Phone: +49 234 52905-0

Fax: +49 234 52905-15

Encyclopedia

Zinc flake process

Zinc flake process

The zinc flake coating process is a sustainable corrosion protection system based on zinc and aluminium. The process is primarily used for smaller parts such as screws, nuts, washers, hinges and also with increased-strength and high-strength quality steels. Significant process advantages here include the HCl-free pre-treatment, the low process temperature (max. 280 °C) and the excellent corrosion protection characteristics (also with aggressive environmental conditions).

Chrome-free corrosion protection

The Coatinc Company offers the zinc flake coating process through its subsidiary company Coatinc NinoCoat N.V. Coatinc NinoCoat is the license holder for the chrome-free corrosion protection method Geomet® from DACRAL in the Benelux countries. This system was originally developed for the automotive industry. Today, many companies in the agricultural, climate technology, machinery construction and locomotive sectors refine their products using the resource-efficient zinc flake coating process.

Efficient production of bulk goods

The corrosion protection process Geomet® provides high-quality corrosion protection for small fastening products with complex geometries. The centrifuge is therefore especially suitable for the refinement process. The fully automatic and environmentally friendly process is complimented by degreasing, blasting, cooling, submersion, drying, sintering and the subsequent packaging services supplied by The Coating Company.

Good parts functionality

Geomet® is a thin, non-electrolytic protective layer consisting of microscopic zinc and aluminium flakes in an inorganic matrix. The minimum layer thickness is 4 μm, but can be adjusted by up to 16 μm depending on the requirements. A minimum layer thickness of 8 µm delivers resistance of 500 hours in the salt spray test. Treated products retain their physical characteristics, are highly dimensionally stable due to their minimal layer thickness and exhibit no brittleness.