Are you an existing customer or do you want to contact us in a different matter? We look forward to hearing from you and will get back to you as soon as possible.

Alternatively, you may want to contact directly one of our locations or our holding company.

Locations

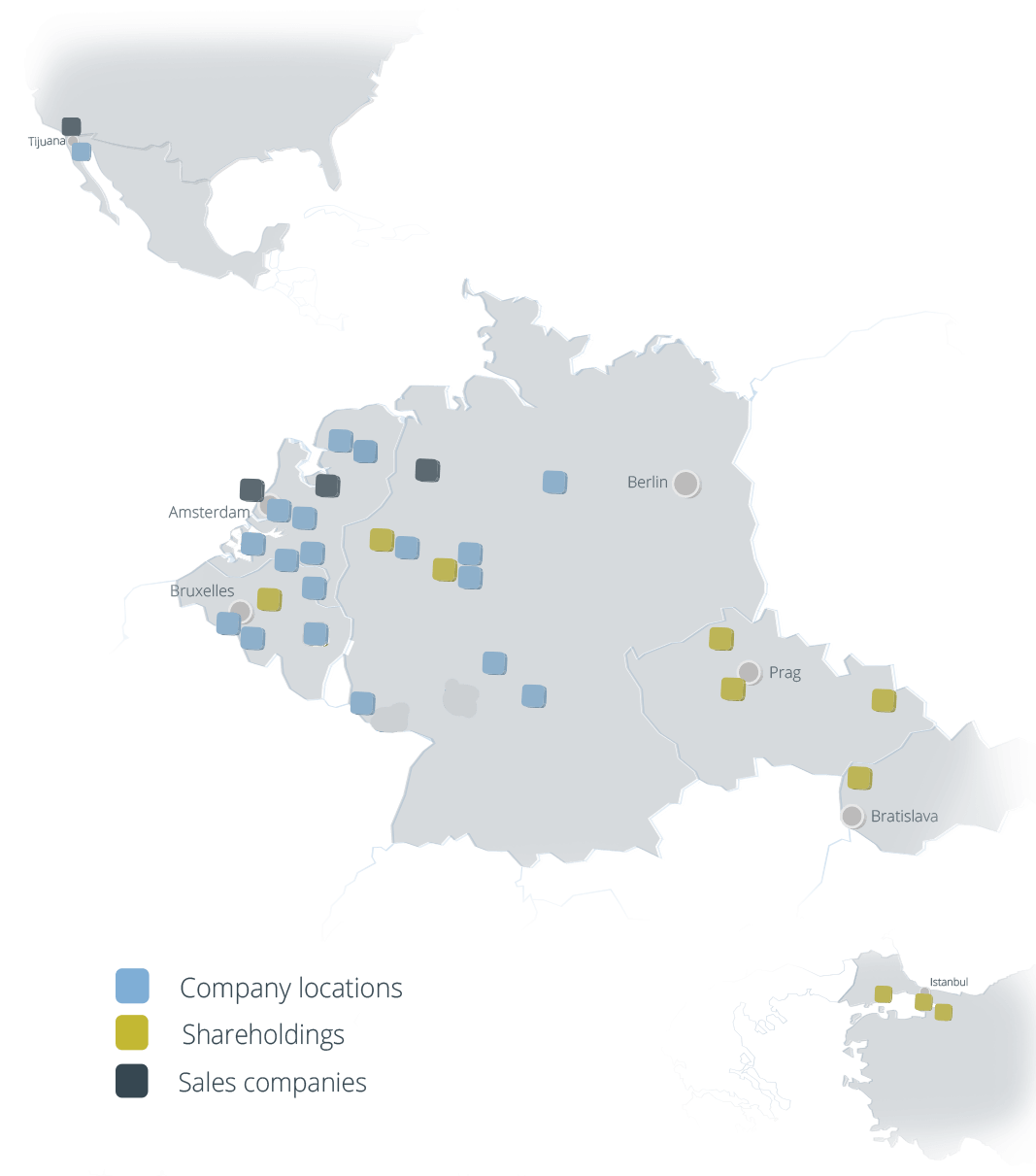

The Coatinc-Network

Slovakia

Netherlands

- Alblasserdam / NL

alblasserdam@coatinc.com - Amsterdam / NL

amsterdam@coatinc.com - Barneveld / NL

nederland@coatinc.com - De Meern / NL

demeern@coatinc.com - Groningen / NL

groningen@coatinc.com - Groningen – Pulverbeschichtung / NL

cgr.verkoop@coatinc.com - Mook / NL

mook@coatinc.com - Mook – PreGa / NL

prega.nl@coatinc.com - Roermond / NL

roermond@coatinc.com - Scherpenzeel / NL

anox@coatinc.com

For enquiries regarding marketing or press matters, please use the following contacts:

Marketing & Press

The Coatinc Company Holding GmbH

Hüttenstraße 45

57223 Kreuztal

Your contact person:

Anna-Maria Ademaj

marketing@coatinc.com

Holding

Headquarter

The Coatinc Company Holding GmbH

Carolinenglückstraße 6-10

44793 Bochum, Germany

Phone: +49 234 52905-0

Fax: +49 234 52905-15

Steel construction

Fantastic

Steel construction

We are committed to fulfilling your requirements from a holistic partner. Our proven capabilities, including hot-dip galvanizing to DIN EN ISO 1461, compliance with DASt directive 022, strict analyses of melt and pretreatment baths as well as quality management certified to DIN ISO 9001:2008 ensure that your requirements in steel construction are perfectly met. With proficient staff and close cooperation with universities and research institutes, we always feature state-of-the-art knowledge and find new ways to enhance our service portfolio. For example, we constantly develop tailored logistics solutions for export jobs.

Quality

Some of our competitors offer very short delivery times, while others offer high galvanizing quality. However, we are interested in only one thing: no compromises, neither in terms of quality nor in speed. We therefore work with optimally networked large plants to to achieve the shortest handling times, even during peak seasons.

Consultation

With individual expert consulting from the planning stage onwards and smart production planning, we are able to save time right from the start. If mechanical reshaping is required, we also have the technical means to provide this service. Speed + quality: This combination has allowed us to gain many years of experience and develop certified quality management and short decision-making processes.

Zink big

When we say that you should only expect the greatest from us, we mean this quite literally. At 19.5 meters in length, one of our steel construction galvanizing pots is very generously sized. This means that individual components measuring up to 19.2 m in size can be dip-coated in one process.