Are you an existing customer or do you want to contact us in a different matter? We look forward to hearing from you and will get back to you as soon as possible.

Alternatively, you may want to contact directly one of our locations or our holding company.

Locations

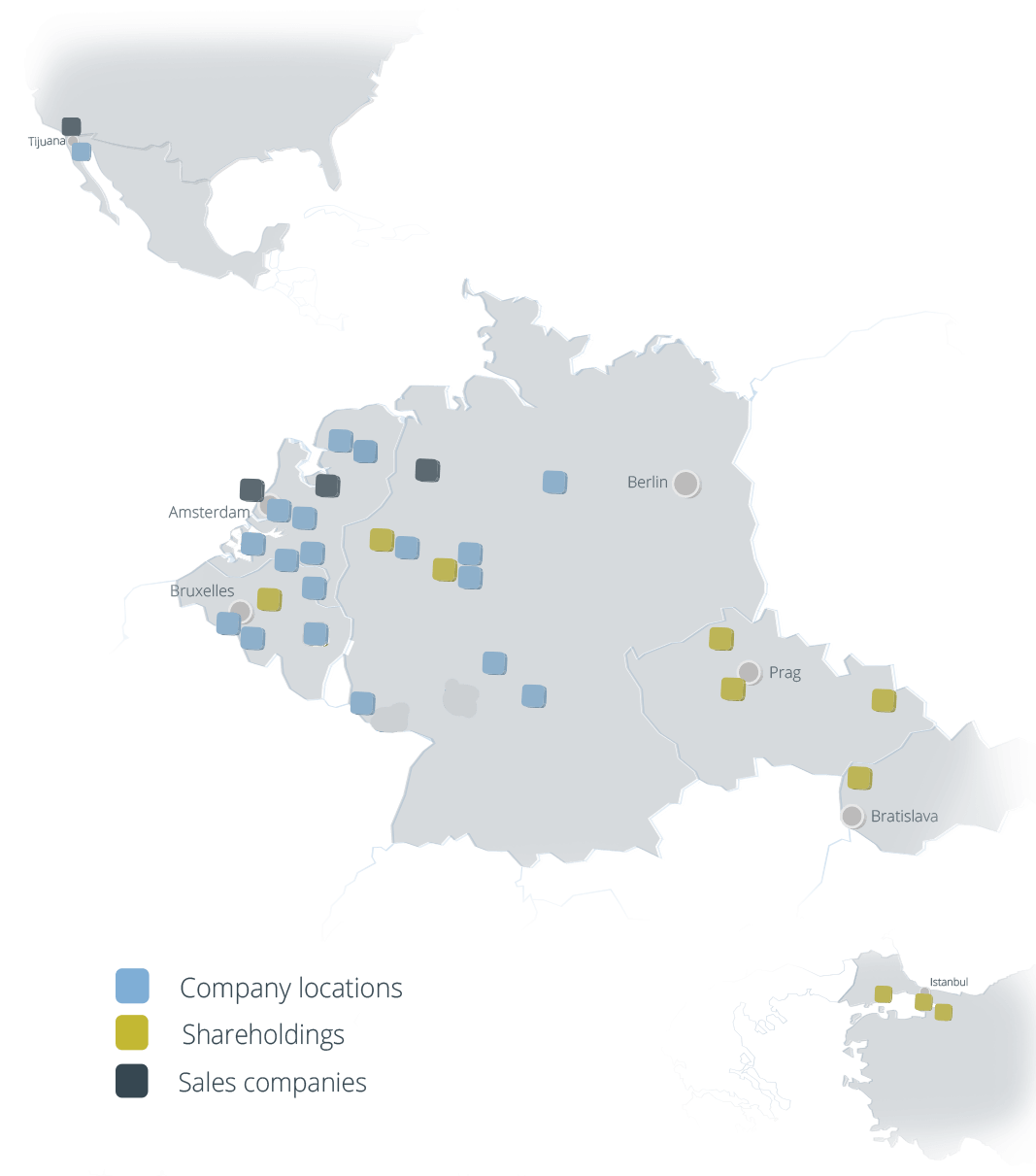

The Coatinc-Network

Slovakia

Netherlands

- Alblasserdam / NL

alblasserdam@coatinc.com - Amsterdam / NL

amsterdam@coatinc.com - Barneveld / NL

nederland@coatinc.com - De Meern / NL

demeern@coatinc.com - Groningen / NL

groningen@coatinc.com - Groningen – Pulverbeschichtung / NL

cgr.verkoop@coatinc.com - Mook / NL

mook@coatinc.com - Mook – PreGa / NL

prega.nl@coatinc.com - Roermond / NL

roermond@coatinc.com - Scherpenzeel / NL

anox@coatinc.com

For enquiries regarding marketing or press matters, please use the following contacts:

Marketing & Press

The Coatinc Company Holding GmbH

Hüttenstraße 45

57223 Kreuztal

Your contact person:

Anna-Maria Ademaj

marketing@coatinc.com

Holding

Headquarter

The Coatinc Company Holding GmbH

Carolinenglückstraße 6-10

44793 Bochum, Germany

Phone: +49 234 52905-0

Fax: +49 234 52905-15

Galvanizing

Corrosion protection – maintenance free

Hot-dip galvanizing

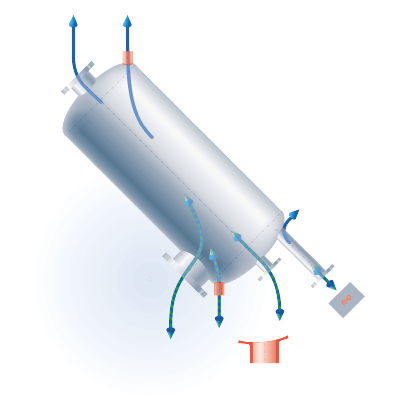

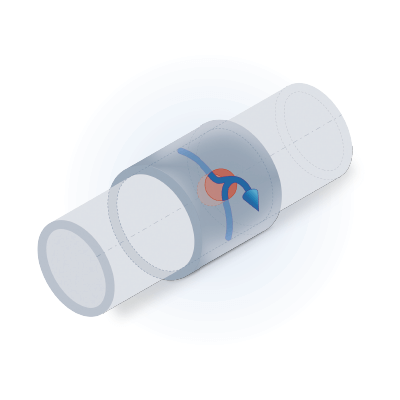

When steel is dipped into molten zinc at a temperature of approximately 450 °C, in the process of galvanizing a layer of iron-zinc alloy with a variety of compositions and then a highly adherent layer of pure zinc builds up on the steel component as a result of inter-diffusion between the liquid zinc and the steel surface.

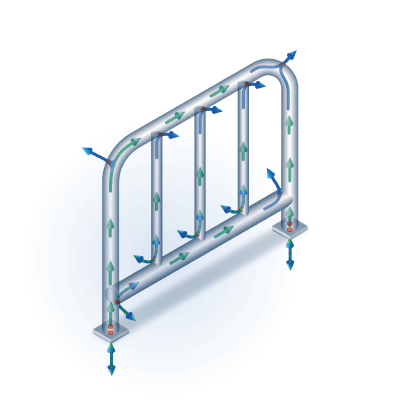

Well applied

After the incoming inspection, the components are charged using a device, taking their shape and type into account. All dirt is removed in the subsequent wet chemical pre-treatment and the steel surface is activated using a flux solution for the following galvanizing process. Rounding out the process, a swift, steep dipping process then occurs in addition to a short, product-dependent dipping time, the cleaning of the bath surface before starting the slow, steep pulling out process and the removal of zinc runs.

Surface quality

The build-up of the iron-zinc alloy layers during the process can be carried out at different speeds. The chemical composition of steel with respect to silicon and phosphorus is of crucial importance, as in certain concentrations these elements accelerate the iron-zinc reaction, and thick, grey zinc coats are formed during galvanizing. In order to achieve perfect visual results, this fact should be taken into account in the planning phase.

Well equipped

For steel components exposed to atmospheric oxygen, hot-dip galvanizing provides highly effective corrosion protection with very long protection duration. For many applications, the protection duration and service life are actually the same. Zinc coats offer low-maintenance or even maintenance-free corrosion protection. When analyzing the costs of corrosion protection measures, including maintenance and repair costs during the service life of steel constructions, hot-dip galvanizing is by far the most economical corrosion protection available, both for steel constructions and many other steel products.

All services at a glance

- Optimal advice

- Material preparation

- Surface finishing

- Secondary operations

- Quality management

- Packaging

- Large projects

- Express delivery

- Export handling

- Customized logistics solutions

Classic surface finishing – explained in 60 seconds.

The process unbeatable for almost 150 years for the sustainable corrosion protection of steel.

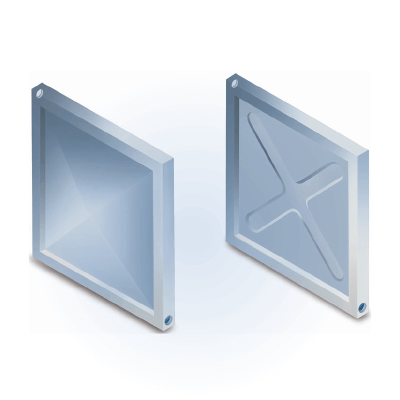

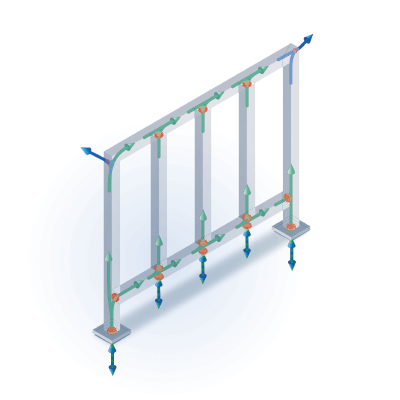

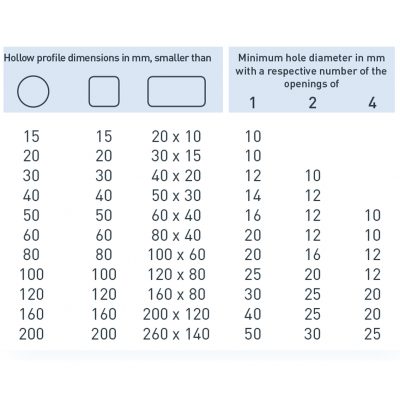

Manufacturing and construction suitable for hot-dip galvanizing

We have compiled a number of useful tips for you on the manufacture and construction suitable for hot-dip galvanizing.

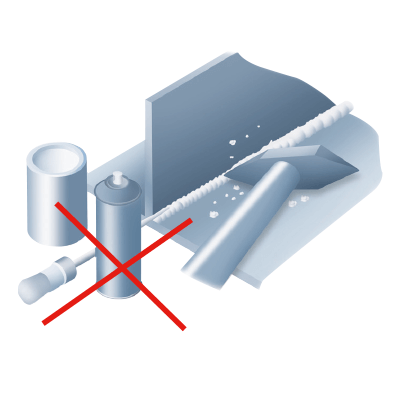

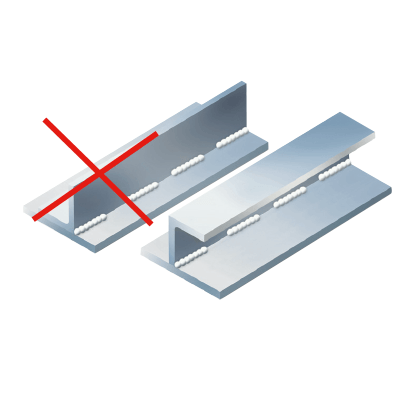

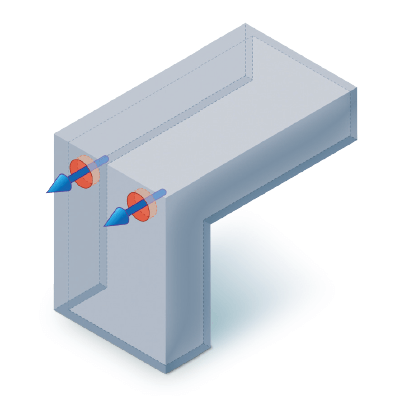

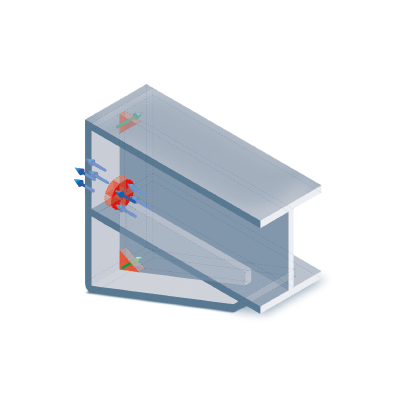

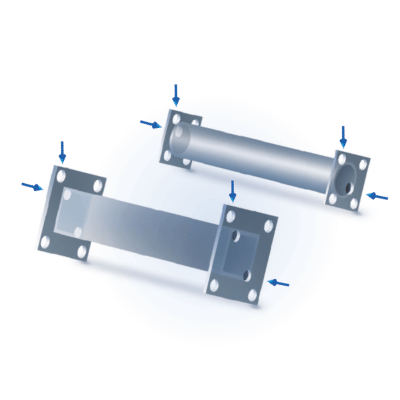

No paint / sprays / weld slag

No decals / markings

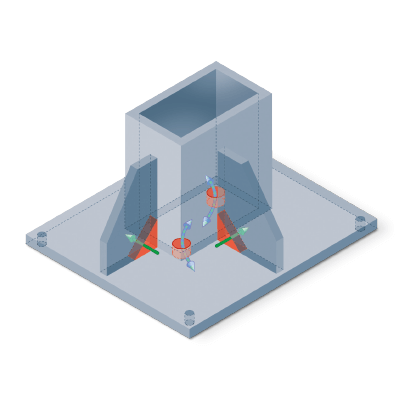

Openings in the base plate area

Do not weld extensively

Vent corners

Notches / bores in the top plate area

Position ventilation and suspension points

Weld in the sleeves in a flush manner

Vent laminations

Introduce beading / tilting

Bores visible

Bores concealed / verifiable

Openings in complex construction