Are you an existing customer or do you want to contact us in a different matter? We look forward to hearing from you and will get back to you as soon as possible.

Alternatively, you may want to contact directly one of our locations or our holding company.

Locations

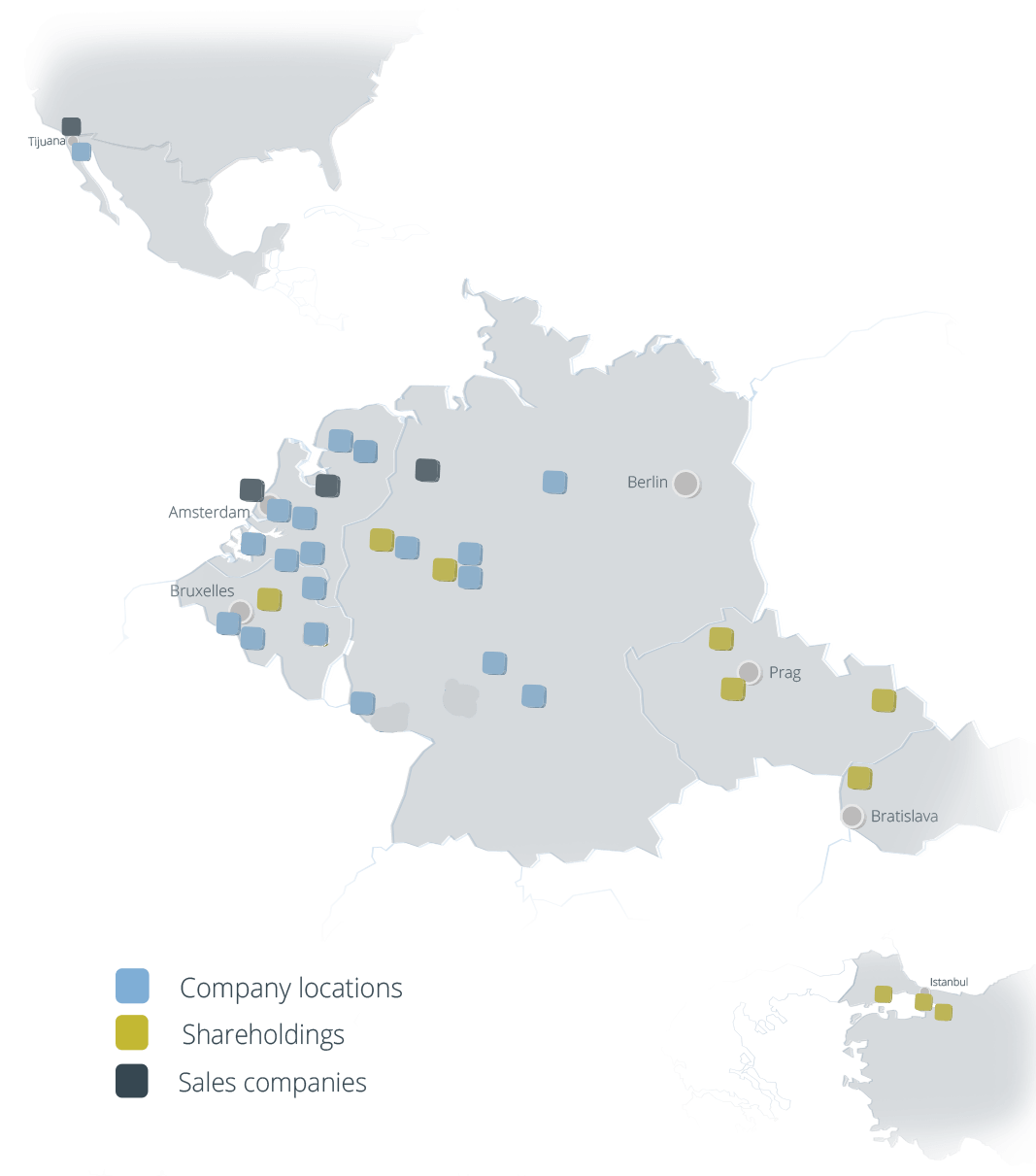

The Coatinc-Network

Slovakia

Netherlands

- Alblasserdam / NL

alblasserdam@coatinc.com - Amsterdam / NL

amsterdam@coatinc.com - Barneveld / NL

nederland@coatinc.com - De Meern / NL

demeern@coatinc.com - Groningen / NL

groningen@coatinc.com - Groningen – Pulverbeschichtung / NL

cgr.verkoop@coatinc.com - Mook / NL

mook@coatinc.com - Mook – PreGa / NL

prega.nl@coatinc.com - Roermond / NL

roermond@coatinc.com - Scherpenzeel / NL

anox@coatinc.com

For enquiries regarding marketing or press matters, please use the following contacts:

Marketing & Press

The Coatinc Company Holding GmbH

Hüttenstraße 45

57223 Kreuztal

Your contact person:

Anna-Maria Ademaj

marketing@coatinc.com

Holding

Headquarter

The Coatinc Company Holding GmbH

Carolinenglückstraße 6-10

44793 Bochum, Germany

Phone: +49 234 52905-0

Fax: +49 234 52905-15

Anodization

Aluminum finishing

Anodization

Our anodization processes achieve even better results than other processes of surface finishing performed by our company group for steel and metal. Our technologies not only allow special protection, but also provide you with the highest flexibility of visual design also by the anodization process. You can count on 100 % durability without having to make concessions regarding the visual effect. On the contrary: Feel free to achieve the results you want! We will support you in the process.

How does anodization work?

Aluminum parts are connected with a positive pole (anode) in a bath containing diluted sulphuric acid. The electrochemical process produces oxygen, which combines directly with the aluminum and produces aluminum oxide. Pigments and other substances can be applied to the newly-created aluminum oxide immediately after anodizing, resulting in the individual metallic coloring. The surface transforms into a sealed layer as a result of the sealing process, in which the pores of the layer are packed tight. This is not only resistant to corrosion, but also remains clean and retains its color. Aluminum after the anodizing is easy to recycle as the aluminum is protected by a metallic layer.

Our anodization / anodizing processes at a glance:

Depending on your objectives, your plan can include diverse processes and characteristics, such as specific layer thicknesses, colors or levels of hardness, wear resistances and high anti-corrosion or antifriction properties.

Colorless anodization – Transparency is everything. And also the best protection.

Anodization is an electrolytic passivation process used to increase the thickness of the natural oxide layer on the surface of aluminum parts and preserves the metal character with a significantly higher resistance to corrosion and long-term protection.

Color anodization – Decide on freedom when making your color choice.

Silver-white, anodized aluminum is timeless, but the process can also be finalized with a wide range of colors without the material losing its natural metal character. The new aluminum oxide being formed during anodizing can absorb pigments or other substances immediately after the anodizing process. This allows perfect coloring of the metal. In addition, the surface is not only very corrosion-resistant thanks to surface sealing, but it also retains color and stays clean. By the way: We can create almost every color desired – just ask us!

Hard anodization – There is nothing like it.

During the process of hard anodizing, the aluminum is given a very thick, hard coating, but at the same time retains a high safety margin of about 5 μm, despite the layer thickness. Hard anodized surfaces withstand extremely high stress and are very wear-resistant. They are scratch-resistant and provide high electrical insulation.

Nituff® – Utmost hardness – with non-stick properties.

Nituff® is a hard anodized layer that has been impregnated with polytetrafluoroethylene (PTFE, i.e. Teflon®) and therefore shows even better properties. For example, this process achieves increased resistance to wear and corrosion as well as optimal non-stick capacity. In addition, a self-lubricating, gliding anodized layer is formed with low friction resistance. Transparency is everything. And also the best protection. Anodization is an electrolytic passivation process used to increase the thickness of the natural oxide layer on the surface of aluminum parts and preserves the metal character with a significantly higher resistance to corrosion and long-term protection.

Masking – All options. No compromises.

With masking, products can be anodized in specific locations or kept in their original condition. The options and techniques for masking are numerous and can be discussed with us based on the reason and type of masking. Our anodization processes at a glance: Depending on your objectives, your plan can include diverse processes and characteristics, such as specific layer thicknesses, colors or levels of hardness, wear resistances and high anti-corrosion or antifriction properties.

Gloss anodization – Decorative and functional.

The process of gloss anodization provides the metal with color as well as shine. The entire spectrum from completely matte to a perfect, reflective surface is possible. The special feature of this process is that gloss anodized surfaces are also extremely smooth.

All services at a glance

- Optimal advice

- Material preparation

- Surface finishing

- Secondary operations

- Quality management

- Packaging

- Large projects

- Express delivery

- Export handling

- Customized logistics solutions

Product dimensions

In principle, we perform various anodizing processes within the scope of our standard product dimensions. However, we also make the maximum (or minimum) possible for you: Please contact us, and we will prepare a specific process bath for individual dimensions.

Technical features

- Layer thicknesses of up to 100 micrometers (μm)

- Hardness up to 600 micro-Vickers

- Higher wear resistance than tempered steel

- Breakdown voltage at about 40 volt/μm

- The aluminum has no black streaks after the process

- Resistant to most chemicals and solvents

- The layer thicknesses can be produced with a very high accuracy

- High corrosion resistance

- Long-term protection

- Environmentally friendly

- Transparent layer

- Customized, metallic colors

Focus on true values – quality, research & development

We are constantly evolving, and for this reason what we do is also groundbreaking. For example, we have a top equipped laboratory for analysis, hardness measurements, salt spray and taber tests, surface roughness measurements, microscopic investigations on anodizing layers, the making of photomicrographs and much more. In short, everything that allows for optimal research and development.

Together with our customers, we always determine the optimal, most economical process for the respective project. We perform all anodization processes with computer-controlled transformers and constantly examine new alloys for their anodizing possibilities.

Our recommendations are confirmed by laboratory tests. Thus we are able to perform anodization services according to the most stringent standards (e.g. MIL-A-8625, BS, NEN and ISO). Our quality assurance system is certified by Lloyds ISO 9001. In addition, we are a member of the International Hard Anodizing Association (IHAA), The Foundation Anodizing (Stanod) and the International Association for Surface Finishing of Metals VIOM – Association International Metal surface treatment.

We work, you benefit:

- Own laboratory and research facilities

- ISO-9001 qualified

- Wide international network

- Active in industry associations