Are you an existing customer or do you want to contact us in a different matter? We look forward to hearing from you and will get back to you as soon as possible.

Alternatively, you may want to contact directly one of our locations or our holding company.

Locations

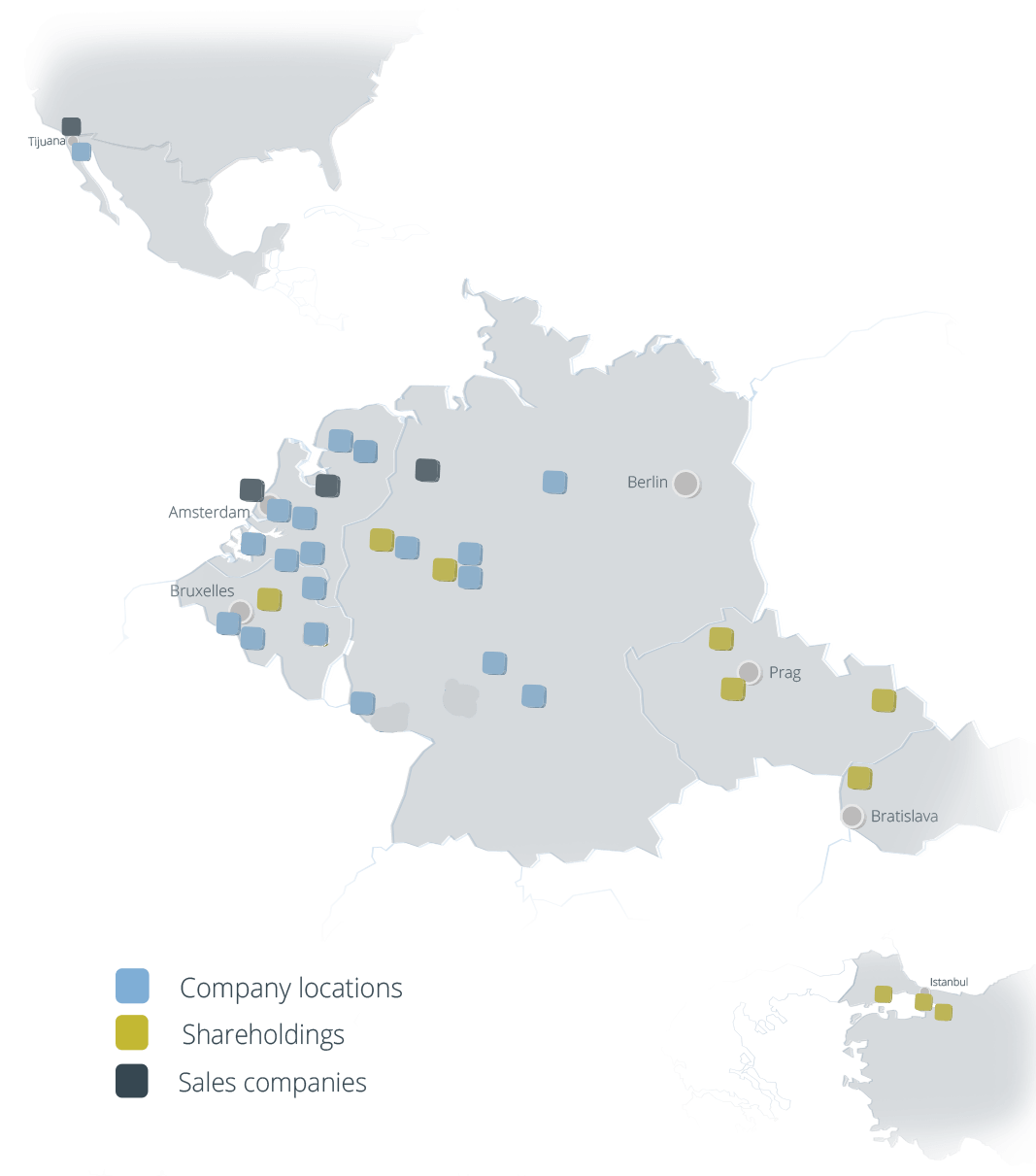

The Coatinc-Network

Slovakia

Netherlands

- Alblasserdam / NL

alblasserdam@coatinc.com - Amsterdam / NL

amsterdam@coatinc.com - Barneveld / NL

nederland@coatinc.com - De Meern / NL

demeern@coatinc.com - Groningen / NL

groningen@coatinc.com - Groningen – Pulverbeschichtung / NL

cgr.verkoop@coatinc.com - Mook / NL

mook@coatinc.com - Mook – PreGa / NL

prega.nl@coatinc.com - Roermond / NL

roermond@coatinc.com - Scherpenzeel / NL

anox@coatinc.com

For enquiries regarding marketing or press matters, please use the following contacts:

Marketing & Press

The Coatinc Company Holding GmbH

Hüttenstraße 45

57223 Kreuztal

Your contact person:

Anna-Maria Ademaj

marketing@coatinc.com

Holding

Headquarter

The Coatinc Company Holding GmbH

Carolinenglückstraße 6-10

44793 Bochum, Germany

Phone: +49 234 52905-0

Fax: +49 234 52905-15

AUTOMOTIVE

Innovativ

Lightweight surfaces for automotive customers

Today, corrosion protection in the automotive industry should not be a matter of weight. Adjustable layer thicknesses in high-temperature galvanization help to achieve a significant reduction of the final weight of components – without any loss of protective properties. For surface quality down to the smallest hollow space – proven by several million components galvanized by us every year for the automotive industry.

The Coatinc Company – so that perfect protection can be easily achieved.

Multi award-winning

The high-temperature galvanized component of the BMW M6 sports car was awarded 1st place in the Hot-Dip Galvanizing Innovation Award 2012. The high-temperature galvanized flood protection system “HWS-mobile” was also awarded 1st place in the Steel Innovation Award 2012.

Precision parts

Compared to the conventional hot-dip galvanizing, HTV (high-temperature galvanizing) creates glossier surfaces with constant micro-roughness, extreme wear and abrasion ability and high accuracy of fit of the components due to tight tolerance limits. The iron-zinc solid solution alloy with hardness values of 260 Hv to 340 Hv provides highly robust stone guard properties.

Electrochemical zinc

Hot-dip galvanizing is largely resistant to mechanical stress, but in very extreme conditions scrapes and scratches may occur. In such cases cathodic protection electrochemically forms a barrier, thereby providing protection against corrosion defects.