Are you an existing customer or do you want to contact us in a different matter? We look forward to hearing from you and will get back to you as soon as possible.

Alternatively, you may want to contact directly one of our locations or our holding company.

Locations

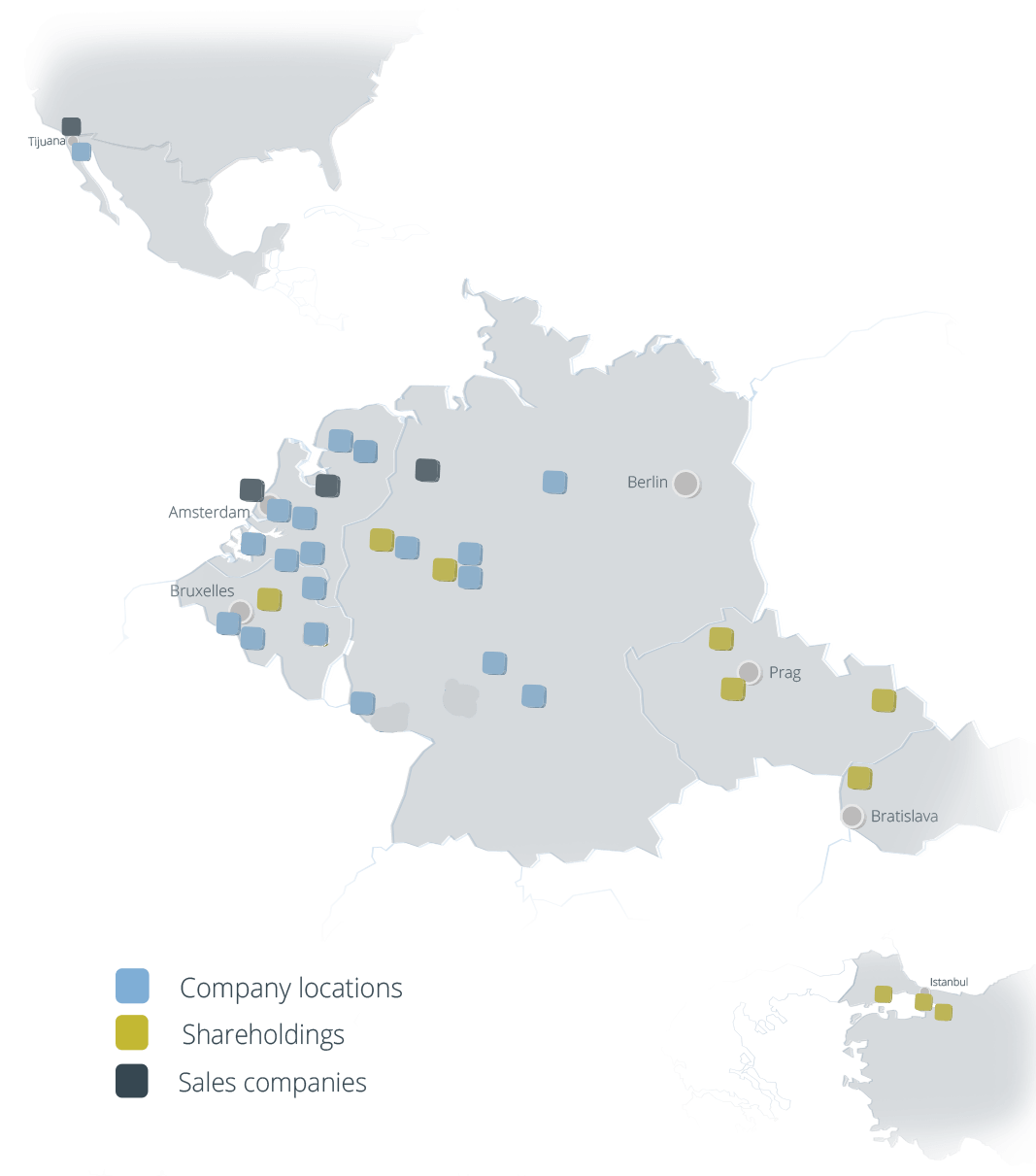

The Coatinc-Network

Slovakia

Netherlands

- Alblasserdam / NL

alblasserdam@coatinc.com - Amsterdam / NL

amsterdam@coatinc.com - Barneveld / NL

nederland@coatinc.com - De Meern / NL

demeern@coatinc.com - Groningen / NL

groningen@coatinc.com - Groningen – Pulverbeschichtung / NL

cgr.verkoop@coatinc.com - Mook / NL

mook@coatinc.com - Mook – PreGa / NL

prega.nl@coatinc.com - Roermond / NL

roermond@coatinc.com - Scherpenzeel / NL

anox@coatinc.com

For enquiries regarding marketing or press matters, please use the following contacts:

Marketing & Press

The Coatinc Company Holding GmbH

Hüttenstraße 45

57223 Kreuztal

Your contact person:

Anna-Maria Ademaj

marketing@coatinc.com

Holding

Headquarter

The Coatinc Company Holding GmbH

Carolinenglückstraße 6-10

44793 Bochum, Germany

Phone: +49 234 52905-0

Fax: +49 234 52905-15

Duplex coating

Zinc and color

The Duplex system

In recent years, hot-dip galvanizing has been increasingly used to provide an additional organic coating to enhance the protection of components exposed to major loads or to combine the customer’s preferred colors with corrosion protection. Essentially, either galvanizing plus powder coating (duplex powder) or wet paint coating systems (duplex system wet) can be applied after hot-dip galvanizing. In most cases, the component surface is first trimmed, swept or given a wet-chemical treatment.

Greatly enhanced duration protection by the duplex system

When the durability of a Duplex system with the durability of a conventional system are compared, it becomes clear that combining two systems will significantly increase protection duration. This synergy effect can increase service life by a factor of up to 2.5. The Duplex system is effective due to the mutual protection of the two components. The zinc coat is protected from atmospheric and chemical impacts by the additional coating, thereby avoiding wear and tear. Furthermore, the hot-dip galvanizing prevents or delays corrosion creep and detached coating in the event of damage.

Applications & benefits of the duplex system

Double or multi-layer systems are recommended for coastal or outdoor use in industrial areas, in chemically contaminated environments, for road salt application in tunnels and on bridges and for products which require a long lifespan. Multi-layer systems are standard with or without galvanizing, depending on the requirements profile. Advantages:

- Functional and decorative

- Excellent appearance – even after long-term use

- Significantly increased protection duration due to synergistic effect

Functionality of multi-layer systems: Duplex system

- A pre-treatment is initially performed with a chrome layer, which both seals the pores in the galvanized surface and acts as an etch primer and substrate protection.

- The application of an epoxide resin onto the substrate then creates a pore density, evens out any unevenness and reaches corners and holes. And last but not least, the epoxide resin acts as a waterproof layer which is resistant to chemical damage.

- Finally, a polyester or polyurethane coating is applied. This not only ensures a beautiful sheen of color but also creates a glossy surface finish.

All services at a glance

- Optimal advice

- Material preparation

- Surface finishing

- Secondary operations

- Quality management

- Packaging

- Large projects

- Express delivery

- Export handling

- Customized logistics solutions