Are you an existing customer or do you want to contact us in a different matter? We look forward to hearing from you and will get back to you as soon as possible.

Alternatively, you may want to contact directly one of our locations or our holding company.

Locations

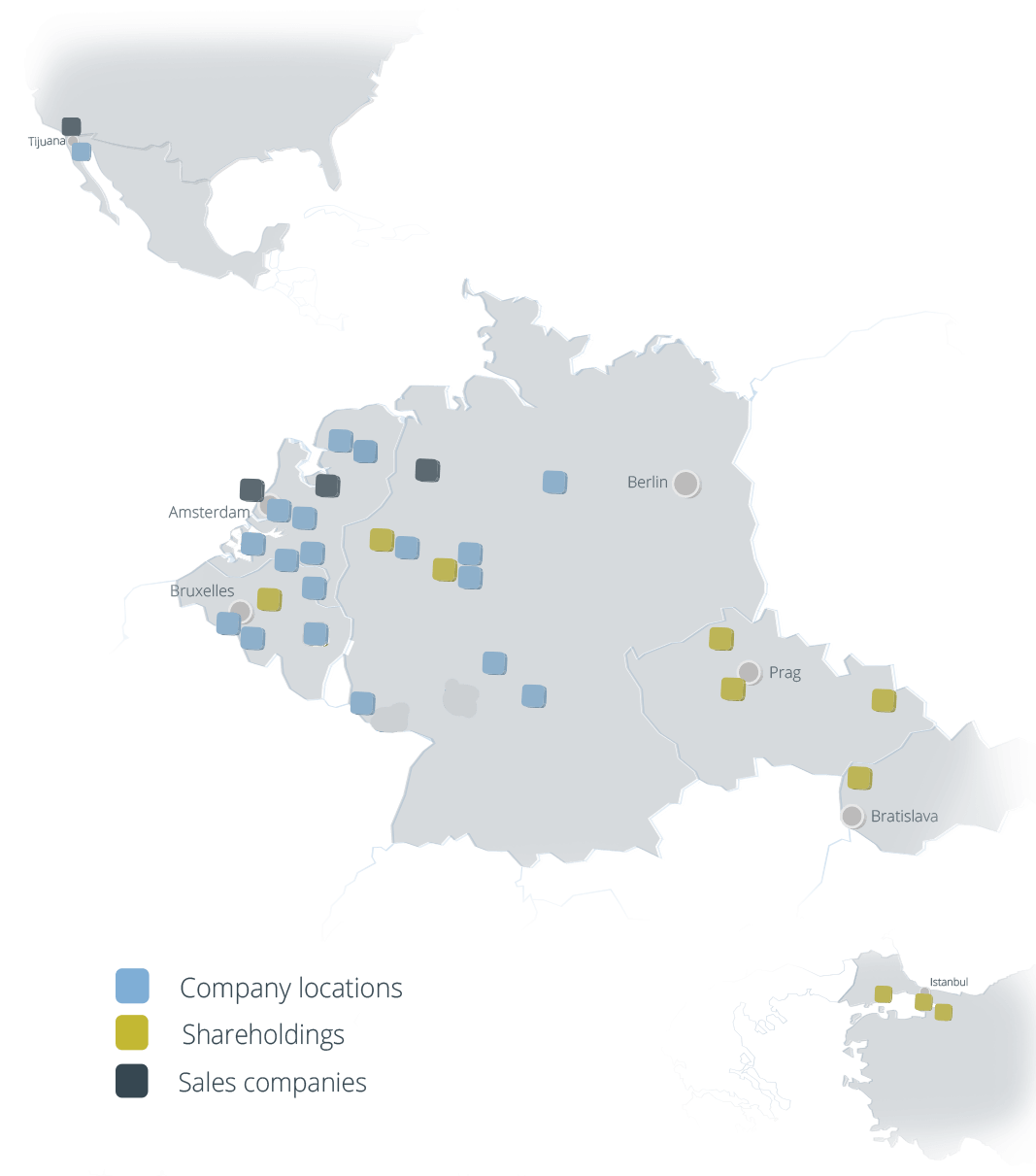

The Coatinc-Network

Slovakia

Netherlands

- Alblasserdam / NL

alblasserdam@coatinc.com - Amsterdam / NL

amsterdam@coatinc.com - Barneveld / NL

nederland@coatinc.com - De Meern / NL

demeern@coatinc.com - Groningen / NL

groningen@coatinc.com - Groningen – Pulverbeschichtung / NL

cgr.verkoop@coatinc.com - Mook / NL

mook@coatinc.com - Mook – PreGa / NL

prega.nl@coatinc.com - Roermond / NL

roermond@coatinc.com - Scherpenzeel / NL

anox@coatinc.com

For enquiries regarding marketing or press matters, please use the following contacts:

Marketing & Press

The Coatinc Company Holding GmbH

Hüttenstraße 45

57223 Kreuztal

Your contact person:

Anna-Maria Ademaj

marketing@coatinc.com

Holding

Headquarter

The Coatinc Company Holding GmbH

Carolinenglückstraße 6-10

44793 Bochum, Germany

Phone: +49 234 52905-0

Fax: +49 234 52905-15

Centrifugal

galvanizing

Specifically for small parts

Centrifugal galvanizing

Automated and semi-automated centrifugal galvanizing has been specially designed for small items requiring a particularly high surface quality and integrity. With nuts, bolts, nails or pins and similar bulk materials, “excess” zinc is released from the components during the centrifugal process. This improves both the integrity and the uniformity of the zinc coating on the surface of the component. In order to prevent the hot-dip galvanized components from sticking together, small components are usually cooled in a water bath.

Coating thickness of “small parts“

Although the terms “small components“ and “spin galvanized goods“ are often used interchangeably in practice, DIN EN ISO 1461 distinguishes between spinning and non-spinning components on the basis of different coating thicknesses. For instance, the standard stipulates that the spinning components should have an average coating thickness of at least 50 μm in comparison to 85 μm for non-spinning components.

Appearance and surface quality

The spin almost completely removes the so-called pure zinc layer. Spinning small components therefore have thinner zinc coats than similar components that have not been subjected to the spinning process. This generally means that the zinc coat surface of the small components will usually have a light grey to medium-grey appearance rather than the typical silvery gloss resulting from standard batch galvanizing. However, it should be noted that this is a purely optical effect which in no way reflects the quality of the corrosion protection.

Typical products of the centrifugal galvanizing

Centrifugal galvanizing is particularly suitable for nails, pins or hooks – i.e. any type of wire nail. The method is also used for small components made from section steel, bar steel and iron sheets. Small components of this type come in all shapes and sizes – such as brackets, butt hinges and cable clamps. Last but not least, bolts, nuts and washers are further typical spin galvanizing products.

Technical features of centrifugal galvanizing

- Very good integrity

- Improved uniformity of the zinc coat on the component surface

- Average coating thickness of at least 50 μm

- High surface quality

All services at a glance

- Optimal advice

- Material preparation

- Surface finishing

- Secondary operations

- Quality management

- Packaging

- Large projects

- Express delivery

- Export handling

- Customized logistics solutions