Are you an existing customer or do you want to contact us in a different matter? We look forward to hearing from you and will get back to you as soon as possible.

Alternatively, you may want to contact directly one of our locations or our holding company.

Locations

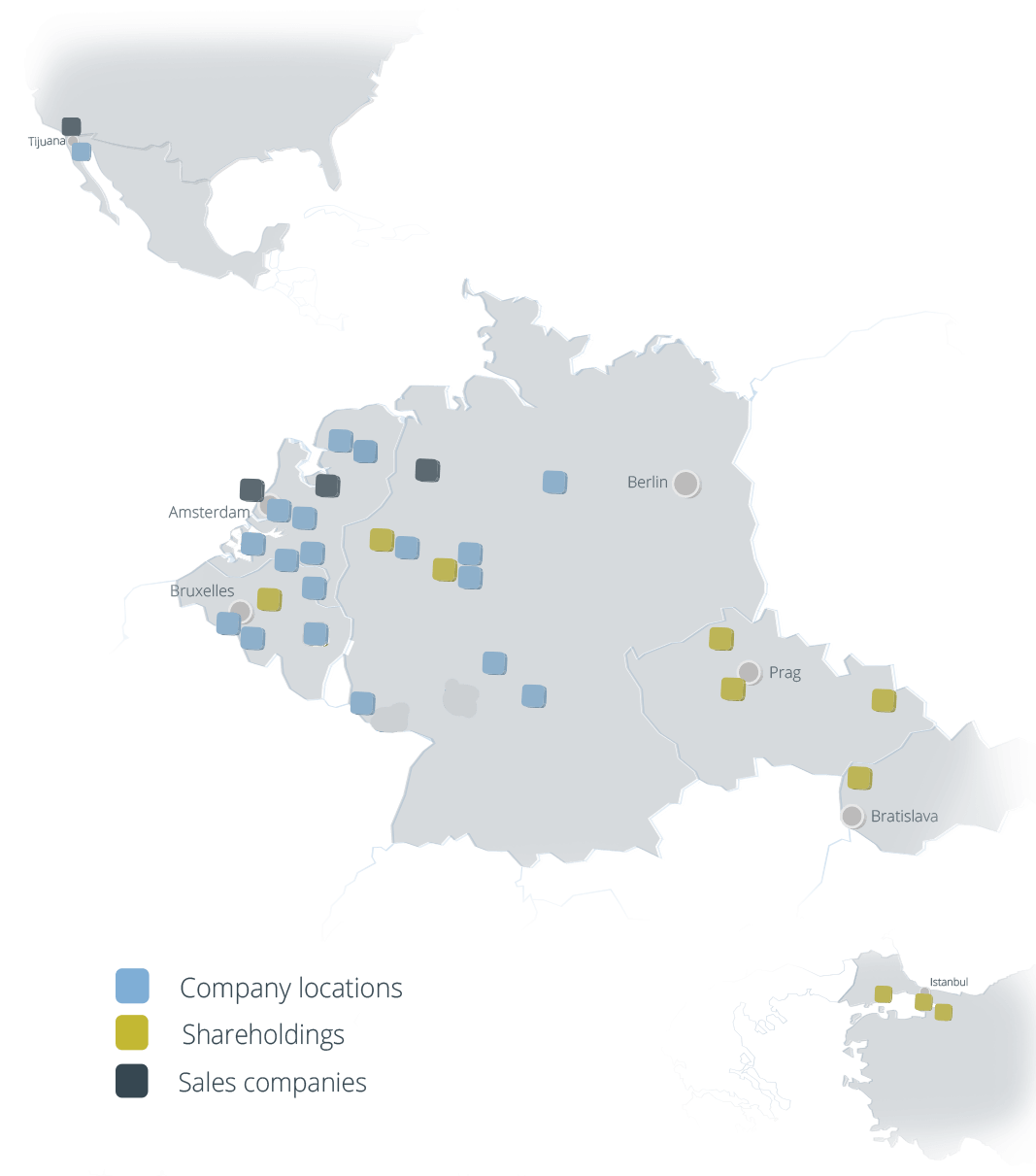

The Coatinc-Network

Slovakia

Netherlands

- Alblasserdam / NL

alblasserdam@coatinc.com - Amsterdam / NL

amsterdam@coatinc.com - Barneveld / NL

nederland@coatinc.com - De Meern / NL

demeern@coatinc.com - Groningen / NL

groningen@coatinc.com - Groningen – Pulverbeschichtung / NL

cgr.verkoop@coatinc.com - Mook / NL

mook@coatinc.com - Mook – PreGa / NL

prega.nl@coatinc.com - Roermond / NL

roermond@coatinc.com - Scherpenzeel / NL

anox@coatinc.com

For enquiries regarding marketing or press matters, please use the following contacts:

Marketing & Press

The Coatinc Company Holding GmbH

Hüttenstraße 45

57223 Kreuztal

Your contact person:

Anna-Maria Ademaj

marketing@coatinc.com

Holding

Headquarter

The Coatinc Company Holding GmbH

Carolinenglückstraße 6-10

44793 Bochum, Germany

Phone: +49 234 52905-0

Fax: +49 234 52905-15

Wet Coating

Ideal surface finish

The wet coating process

First of all, it should be noted that the color groups, surface finish and gloss level can be selected for wet coating in the same way as in the powder coating process. The exact specification of the coating can be designed in accordance with the technical requirements and customer preferences. The Technical Delivery Terms and Test Regulations for Anti-Corrosion Coatings on Steel Structures (TL/TP-KOR) and the specifications of the Federal Highway Research Institute (BASt) are often applied during the wet coating process. Regardless of this, layer systems can be implemented in consultation with the paint manufacturers.

At least three variants are possible

Structure in accordance with TL/TP-KOR

- Sweep blasting SA 2 ½ in accordance with EN ISO 12944-4

- Primer (2-EP) and topcoat (2K-PUR) – 97 sheet

- each 80 μm

Structure in accordance with TL/TP-KOR hydro-priming

- Clean surface & use within 24 hours after galvanizing

- Primer – 91 sheet (1K-hydro) and topcoat – 87 sheet (2K-PUR)

- each 80 μm

High-quality coating system

- Clean surface & use within 24 hours after galvanizing

- Primer (2K-EP) or (1K-hydro) and topcoat – 87 sheet (2K-PUR)

- each 80 μm

Say goodbye to the standard – welcome the best solution

Describe your project to us and we will offer you the right solution from the full range of our possibilities. Determine color groups, surface finish, and the intensity of the shine yourself. Depending on the specification of the coating, technical requirements, and your individual needs, we can even deliver a concept that can be implemented with our staff at your site.

Trust our experts who know how to apply paint efficiently, durably and brilliantly to steel or hot-dip galvanized components. By the way, also for individual solutions or special requirements, for example, specific hygienic standards of the food industry and fire protection R30 to R90 (EN 1090).

In order to guarantee globally recognized quality standards, we also employ employees at the Mannheim and Groß-Rohrheim locations, certified as inspectors for FROSIO, the world’s leading institution for corrosion protection solutions.

Everything has already been done – bundled know-how for brilliant results

Our team of specialists are focused on the abrasive blasting and wet painting of steel and hot-dip galvanized steel using a wide range of different spraying techniques. We cover composite structures as well as multi-layer systems with varnishes of alkyd resin, epoxy or polyurethane in all conceivable colors. Whether RAL, DB, NCS or special tones – thanks to our close supplier relationships, the full range of colors is ensured through consultation, technical support and warranty.

Functional paints, as well as classic systems, can be implemented by our staff at your site. And we offer the service that our finishing specialists will work directly in your factory for oversized component geometries.

In addition, we have mobile machines, which can be used anywhere in the world within our group of companies. Our services are applied in various fields, including vehicle construction and energy engineering.

The diverse areas of application:

- Sheet metal working

- Civil engineering and construction

- Steel, indoor, machine and vehicle construction

- Off-shore, Petro-wind, energy and gas industry

- Road construction: such as lanterns and masts, bridges and noise barriers

All services at a glance

- Optimal advice

- Material preparation

- Surface finishing

- Secondary operations

- Quality management

- Packaging

- Large projects

- Express delivery

- Export handling

- Customized logistics solutions

Further information

The properties vary between the three described systems. Some systems offer more protection than others, but also require longer lead times. Talk to us to learn about many further details and obtain professional advice.