Are you an existing customer or do you want to contact us in a different matter? We look forward to hearing from you and will get back to you as soon as possible.

Alternatively, you may want to contact directly one of our locations or our holding company.

Locations

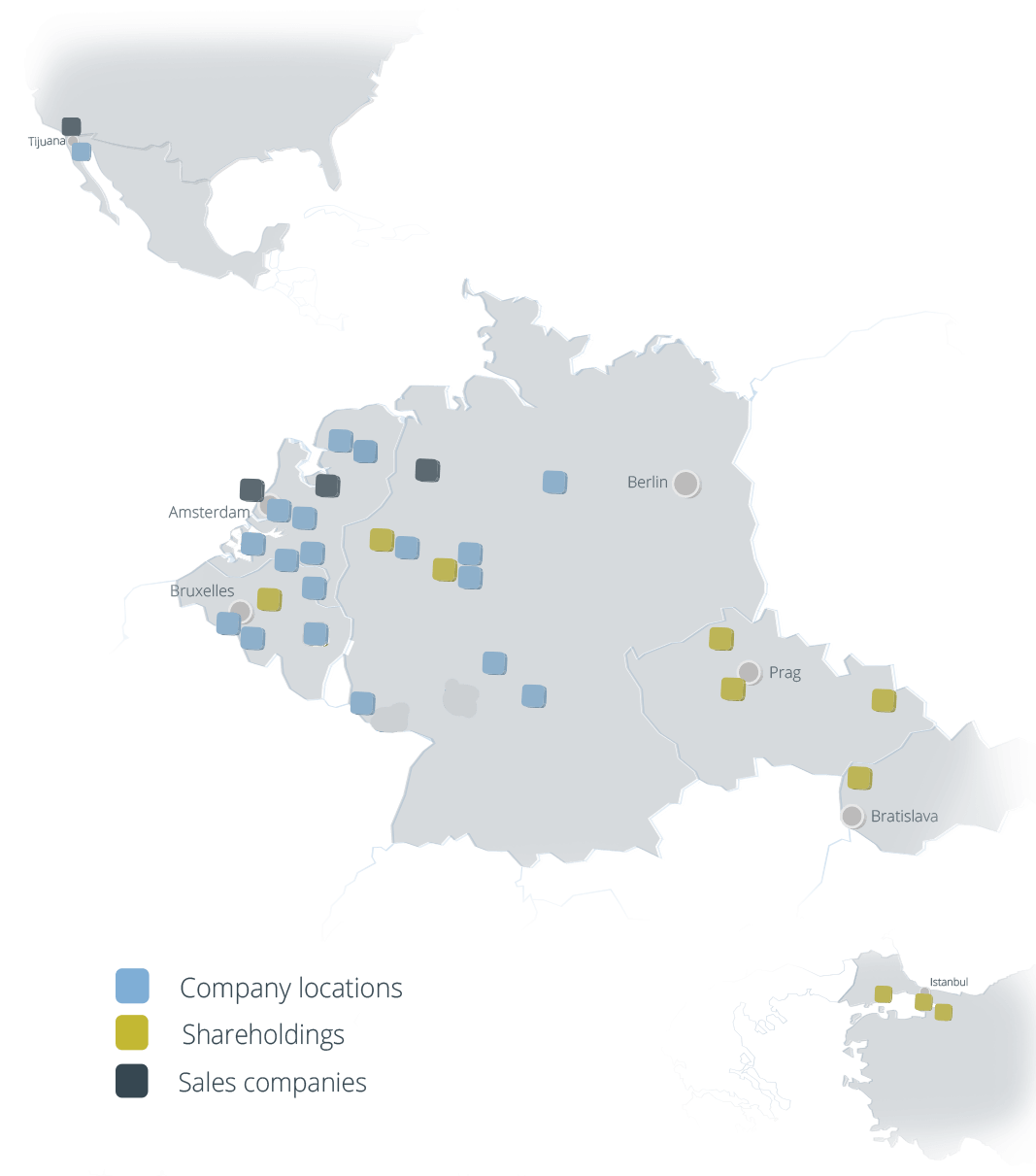

The Coatinc-Network

Slovakia

Netherlands

- Alblasserdam / NL

alblasserdam@coatinc.com - Amsterdam / NL

amsterdam@coatinc.com - Barneveld / NL

nederland@coatinc.com - De Meern / NL

demeern@coatinc.com - Groningen / NL

groningen@coatinc.com - Groningen – Pulverbeschichtung / NL

cgr.verkoop@coatinc.com - Mook / NL

mook@coatinc.com - Mook – PreGa / NL

prega.nl@coatinc.com - Roermond / NL

roermond@coatinc.com - Scherpenzeel / NL

anox@coatinc.com

For enquiries regarding marketing or press matters, please use the following contacts:

Marketing & Press

The Coatinc Company Holding GmbH

Hüttenstraße 45

57223 Kreuztal

Your contact person:

Anna-Maria Ademaj

marketing@coatinc.com

Holding

Headquarter

The Coatinc Company Holding GmbH

Carolinenglückstraße 6-10

44793 Bochum, Germany

Phone: +49 234 52905-0

Fax: +49 234 52905-15

Powder coating

Color corrosion protection

The powder coating process

Together with affiliated and our own companies, we offer our customers a one-stop powder coating process at several locations. The use of powder coating using polyester resin (SP) is standard for external applications. This is particularly resistant to weathering (good UV resistance). The chalking and discoloration behavior is significantly lower than that of epoxy resin powder (EP), which is primarily used for priming due to their high chemical and diffusion resistance.

The following layer structures are possible

- Powder-priming as an option for a better surface finish (optics)

- Powder epoxy primer as an option for chemical stability (corrosion protection)

- Powder-SP topcoat is our standard for hot-dip galvanized surfaces

- Clear-coat powder coating to add gloss to matt pearl effect colors, for example

- Anti-graffiti powder coating on request, for easier to clean

Color groups

- Single coats according to RAL or special colors on request

- Metallic coatings according to RAL or DB colors or on request

- Iron mica coatings according to RAL, DB colors or on request

- Pearl mica coatings RAL with major color deviations

(single layer only in matt, gloss is possible by adding another clear coating)

Surface finish

- Glossy is our standard in all RAL and DB colors

- Coarse texture only on special request

- Fine texture possible for all DB colors

(RAL 9006, RAL 9007 and other colors on request)

(unless otherwise specified at the factory, i.e. at Coatinc Würzburg).

All services at a glance

- Optimal advice

- Material preparation

- Surface finishing

- Secondary operations

- Quality management

- Packaging

- Large projects

- Express delivery

- Export handling

- Customized logistics solutions

Powder coating – explained in 60 seconds

Square meter calculation of components

We have compiled the calculation methods for square meter calculation for you here.

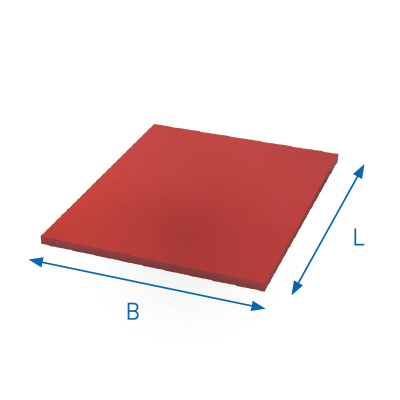

Powder coating of sheet metal, perforated sheet metal & expanded metal

- L x W x 2 ( total area incl. angled surfaces)

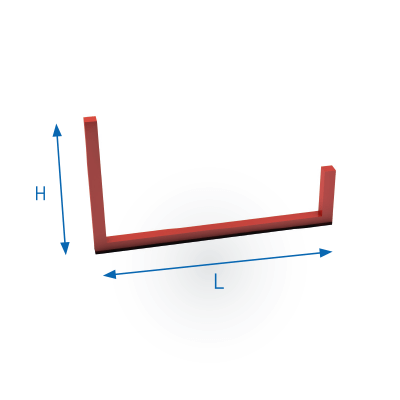

Powder coating of railings and blacksmith products

- Flat iron: < 70 mm = L x H

- Flat iron: > 70 mm = L x H x 1.5

Powder coating of two-dimensional structures

- Industrial and decorative blacksmith products: L x H (unless the profile surface is larger)

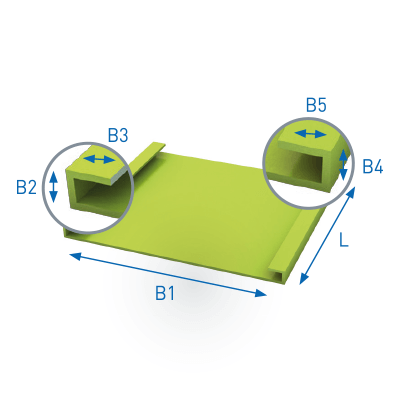

Powder coating of edged sheets (smooth, punched), expanded metal

- (B1 + B2 + B3 + B4 + B5) x L x 2

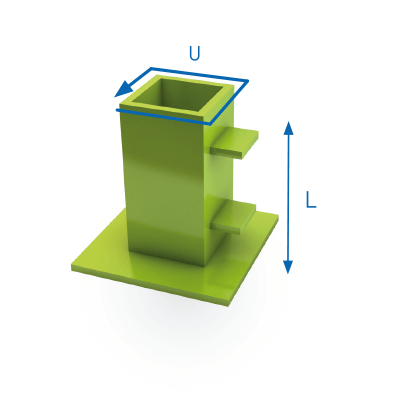

Powder coating of poles

- Profile circumference x L x 1.25 (minimum circumference = 150 mm)

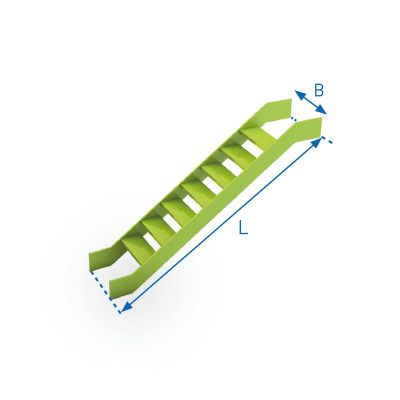

Powder coating of stairs

- Stairs with steps: L x W x 2

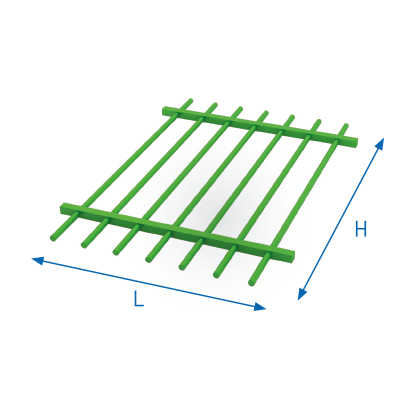

Powder coating of railings and fence elements

- Rail and fence elements (up to cross bars): < 70 x 8 mm distance of cross bars at least 100 L x H

- Rail and fence elements at the top: > 70 x 8 mm distance of cross bars at least 100 L x H x 1.50

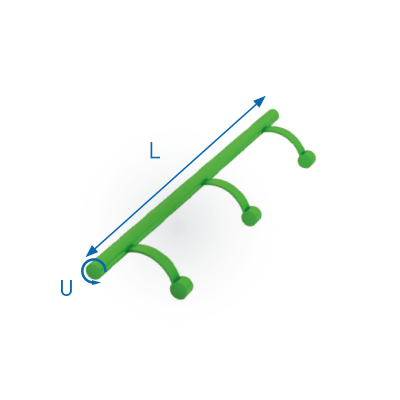

Powder coating of hand rails

- Hand rail: Min. 150 mm x L

- Hand rail with bracket: Min. 200 mm x L

- Curved and tiered hand rail: Min. 150 mm x L x 2

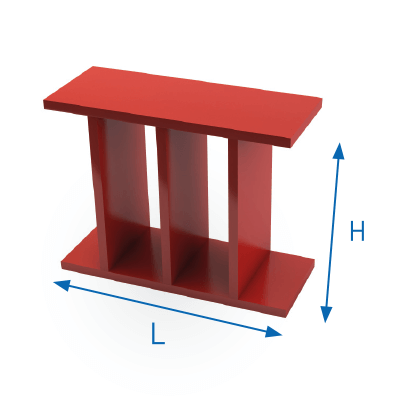

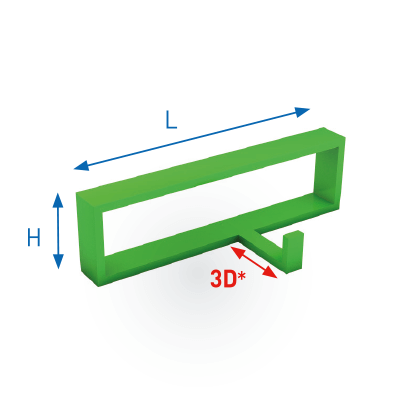

Coating of three-dimensional structures

- L x H (x 2)