High-temperature galvanizing

Are you an existing customer or do you want to contact us in a different matter? We look forward to hearing from you and will get back to you as soon as possible.

Alternatively, you may want to contact directly one of our locations or our holding company.

Locations

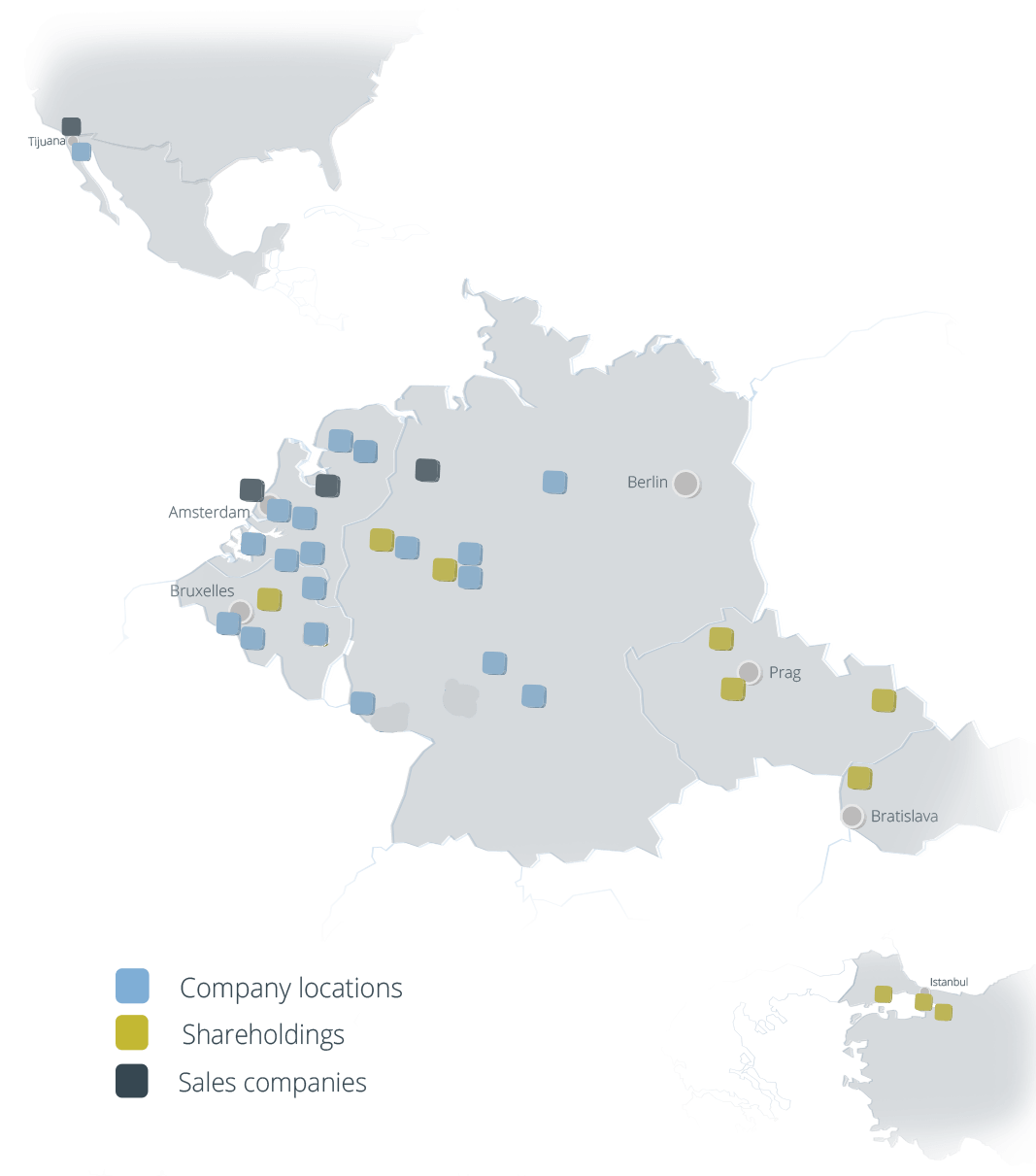

The Coatinc-Network

Netherlands

- Alblasserdam / NL

alblasserdam@coatinc.com - Amsterdam / NL

amsterdam@coatinc.com - Barneveld / NL

nederland@coatinc.com - De Meern / NL

demeern@coatinc.com - Groningen / NL

groningen@coatinc.com - Groningen – Pulverbeschichtung / NL

cgr.verkoop@coatinc.com - Mook / NL

mook@coatinc.com - Mook – PreGa / NL

prega.nl@coatinc.com - Roermond / NL

roermond@coatinc.com - Scherpenzeel / NL

anox@coatinc.com

For enquiries regarding marketing or press matters, please use the following contacts:

Marketing & Press

The Coatinc Company Holding GmbH

Hüttenstraße 45

57223 Kreuztal

Your contact person:

Anna-Maria Ademaj

marketing@coatinc.com

Holding

Headquarter

The Coatinc Company Holding GmbH

Carolinenglückstraße 6-10

44793 Bochum, Germany

Phone: +49 234 52905-0

Fax: +49 234 52905-15

Encyclopedia

High-temperature galvanizing

High-temperature galvanizing

High-temperature galvanizing is a more advanced hot-dip metal coating process, where steel components are coated in a ceramic-lined, induction-heated pot at temperatures between 560 and 630 °C. Depending on the customer’s specification, very thin coats of zinc ranging from approximately 25 µm up to 80 µm in accordance with DIN EN ISO 1461 may be applied. The protective effect of a high-temperature zinc alloy layer is identical to that obtained in a normal-temperature galvanizing process. The benefits of this process also include special product properties such as accuracy of fit, coatability and greater surface hardness.

High-temperature galvanizing is a more advanced hot-dip metal coating process, where steel components are coated in a ceramic-lined, induction-heated pot at temperatures between 560 and 630 °C. Depending on the customer’s specification, very thin coats of zinc ranging from approximately 25 µm up to 80 µm in accordance with DIN EN ISO 1461 may be applied. The protective effect of a high-temperature zinc alloy layer is identical to that obtained in a normal-temperature galvanizing process. The benefits of this process also include special product properties such as accuracy of fit, coatability and greater surface hardness.