Anodic oxidation

Are you an existing customer or do you want to contact us in a different matter? We look forward to hearing from you and will get back to you as soon as possible.

Alternatively, you may want to contact directly one of our locations or our holding company.

Locations

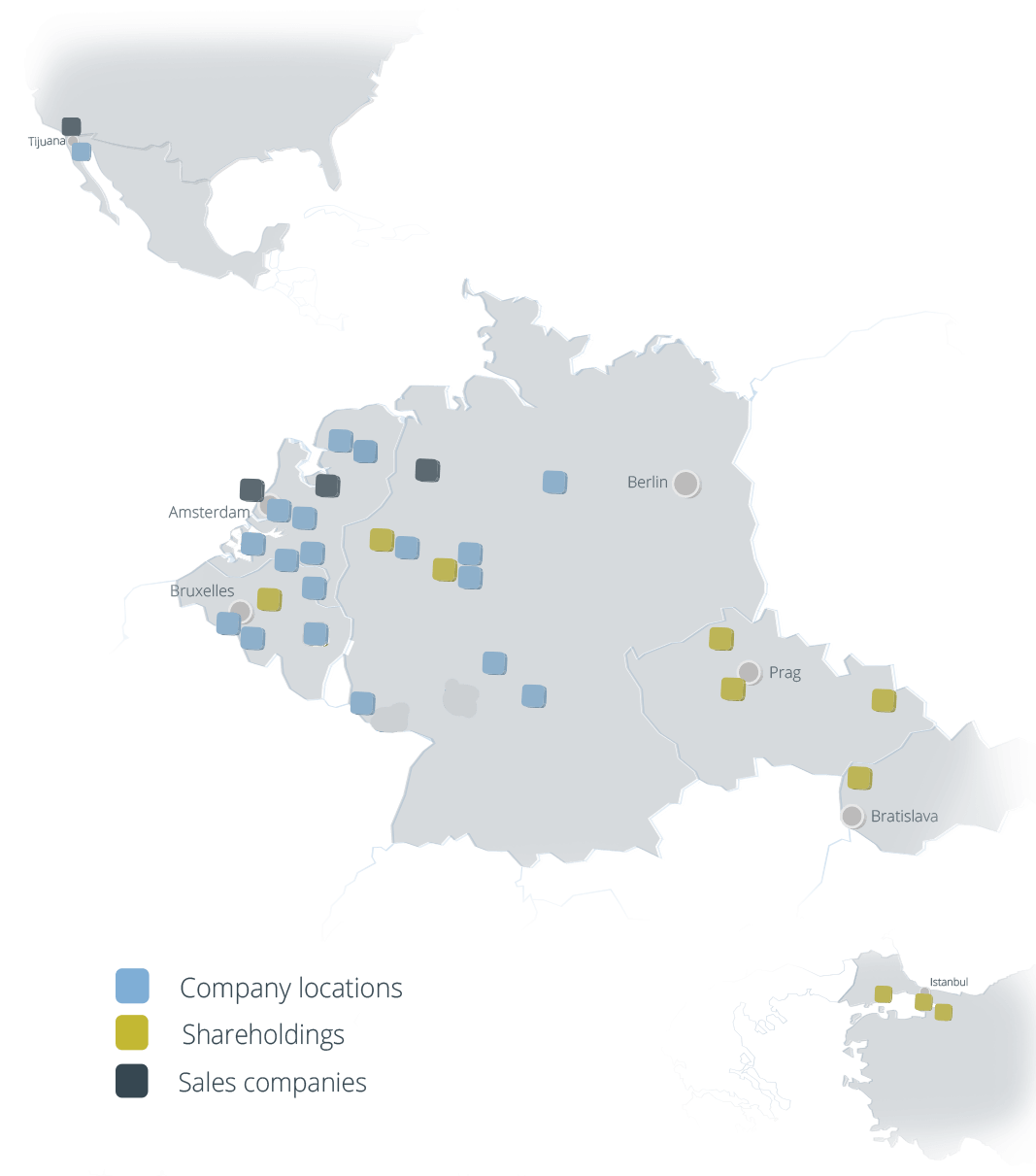

The Coatinc-Network

Slovakia

Netherlands

- Alblasserdam / NL

alblasserdam@coatinc.com - Amsterdam / NL

amsterdam@coatinc.com - Barneveld / NL

nederland@coatinc.com - De Meern / NL

demeern@coatinc.com - Groningen / NL

groningen@coatinc.com - Groningen – Pulverbeschichtung / NL

cgr.verkoop@coatinc.com - Mook / NL

mook@coatinc.com - Mook – PreGa / NL

prega.nl@coatinc.com - Roermond / NL

roermond@coatinc.com - Scherpenzeel / NL

anox@coatinc.com

For enquiries regarding marketing or press matters, please use the following contacts:

Marketing & Press

The Coatinc Company Holding GmbH

Hüttenstraße 45

57223 Kreuztal

Your contact person:

Anna-Maria Ademaj

marketing@coatinc.com

Holding

Headquarter

The Coatinc Company Holding GmbH

Carolinenglückstraße 6-10

44793 Bochum, Germany

Phone: +49 234 52905-0

Fax: +49 234 52905-15

Encyclopedia

Anodic oxidation

Anodic oxidation

Aluminum finishing by Coatinc

Our anodic oxidation processes achieve even better results than other processes of surface finishing performed by our company group for steel and metal. Our technologies not only allow special protection, but also provide you with the highest flexibility of visual design. You can count on 100 % durability without having to make concessions regarding the visual effect. On the contrary: Feel free to achieve the results you want! We will support you in the process.

How does anodic oxidation work?

Aluminum parts are connected with a positive pole (anode) in a bath containing diluted sulphuric acid. The electrochemical process produces oxygen, which combines directly with the aluminum and produces aluminum oxide. Pigments and other substances can be applied to the newly-created aluminum oxide immediately after anodizing, resulting in the individual metallic colouring. The surface transforms into a sealed layer as a result of the sealing process, in which the pores of the layer are packed tight. This is not only resistant to corrosion, but also remains clean and retains its colour. Anodized aluminum is easy to recycle as the aluminum is protected by a metallic layer.

Product dimensions

In principle, we perform various anodic oxidation processes within the scope of our standard product dimensions. However, we also make the maximum (or minimum) possible for you: Please contact us, and we will prepare a specific process bath for individual dimensions.

Technical features

- Layer thicknesses of up to 100 micrometers (μm)

- Hardness up to 600 micro-Vickers

- Higher wear resistance than tempered steel

- Breakdown voltage at about 40 volt/μm

- The aluminum has no black streaks after the process

- Resistant to most chemicals and solvents

- The layer thicknesses can be produced with a very high accuracy

- High corrosion resistance

- Long-term protection

- Environmentally friendly

- Transparent layer

- Customized, metallic colors