Are you an existing customer or do you want to contact us in a different matter? We look forward to hearing from you and will get back to you as soon as possible.

Alternatively, you may want to contact directly one of our locations or our holding company.

Locations

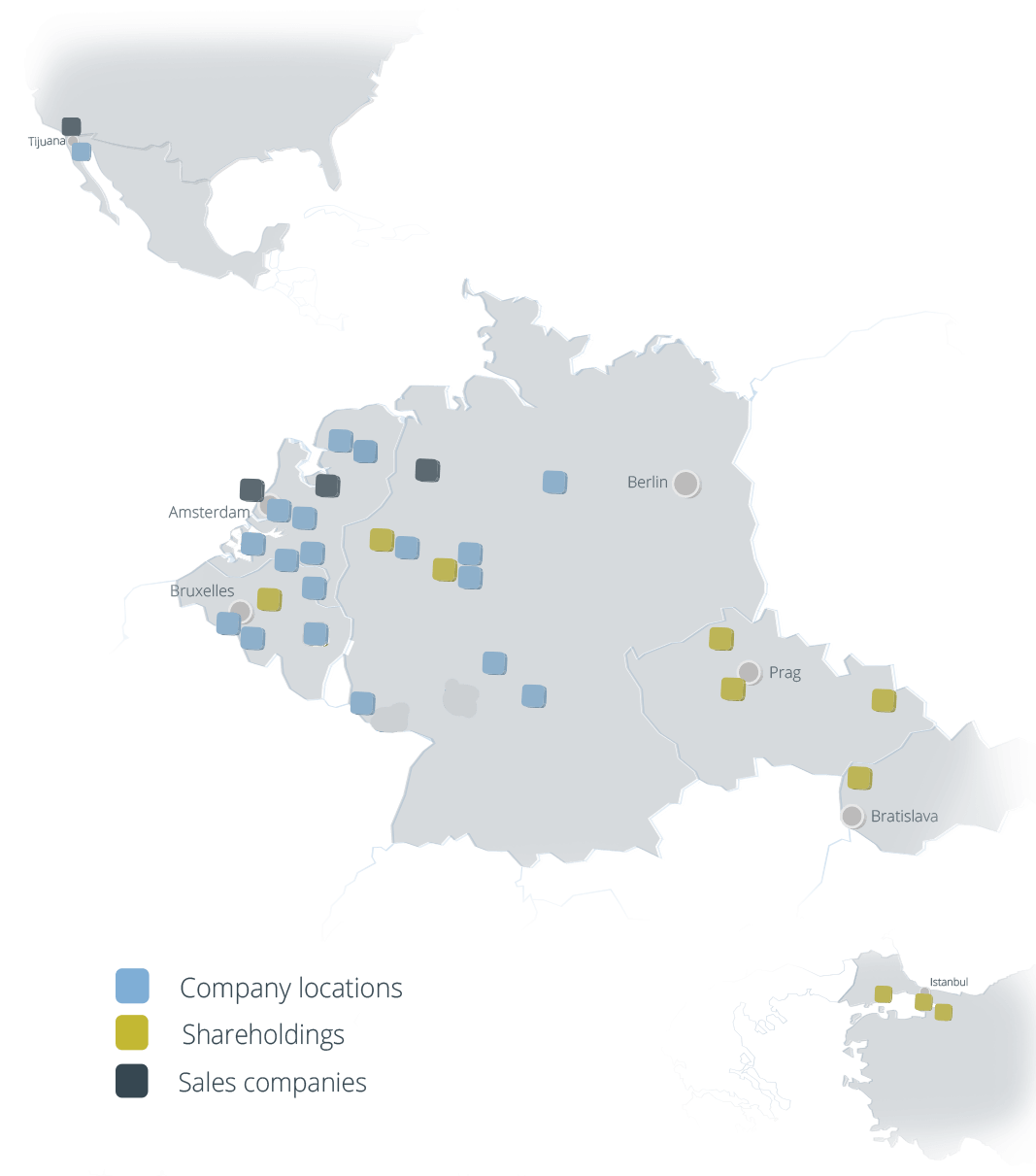

The Coatinc-Network

Slovakia

Netherlands

- Alblasserdam / NL

alblasserdam@coatinc.com - Amsterdam / NL

amsterdam@coatinc.com - Barneveld / NL

nederland@coatinc.com - De Meern / NL

demeern@coatinc.com - Groningen / NL

groningen@coatinc.com - Groningen – Pulverbeschichtung / NL

cgr.verkoop@coatinc.com - Mook / NL

mook@coatinc.com - Mook – PreGa / NL

prega.nl@coatinc.com - Roermond / NL

roermond@coatinc.com - Scherpenzeel / NL

anox@coatinc.com

For enquiries regarding marketing or press matters, please use the following contacts:

Marketing & Press

The Coatinc Company Holding GmbH

Hüttenstraße 45

57223 Kreuztal

Your contact person:

Anna-Maria Ademaj

marketing@coatinc.com

Holding

Headquarter

The Coatinc Company Holding GmbH

Carolinenglückstraße 6-10

44793 Bochum, Germany

Phone: +49 234 52905-0

Fax: +49 234 52905-15

High-temperature

galvanizing (HTV)

precision galvanizing

High-temperature galvanizing

High-temperature galvanizing is a more advanced hot-dip metal coating process, where steel components are coated in a ceramic-lined, induction-heated pot at temperatures between 560 and 620 °C. Depending on the customer’s specification, very thin coats of zinc ranging from approximately 25 µm up to 80 µm in accordance with DIN EN ISO 1461 may be applied. The protective effect of a high-temperature zinc alloy layer is identical to that obtained in a normal-temperature galvanizing process. The benefits of this process also include special product properties such as accuracy of fit, coatability and greater surface hardness.

Accuracy of fit

Due the higher galvanizing temperature and the substantially lower viscosity of the liquid zinc, the zinc alloy flows more easily off the component. After previous coordination of the components, even the smallest drill holes or threads can be hot-dip galvanized without the need to rework them afterwards. This is particularly important to meet the requirements of ready-to-mount products.

Extremely thin, extremely hard – high-temperature galvanization

The iron-zinc alloy layers produced in the high-temperature galvanization process feature a high surface hardness with improved abrasion and wear resistance. This provides vehicle parts exposed to flying objects with additional protection. Special process management results in extremely thin, lightweight layers of zinc with a narrow variation range that can be reproduced.

Coatability

In high-temperature galvanizing the controllable zinc layer thickness, which is almost independent of the material, provides a high level of surface precision. There is virtually no uncontrolled growth of the zinc layer thickness, particularly on weld seams and in edge areas. This reduces costly and time-consuming finishing to a minimum. Furthermore, the fine micro-roughness of the zinc layer is an ideal etch primer for all subsequent coating systems.

All services at a glance

- Optimal advice

- Material preparation

- Surface finishing

- Secondary operations

- Quality management

- Packaging

- Large projects

- Express delivery

- Export handling

- Customized logistics solutions