White rust

Are you an existing customer or do you want to contact us in a different matter? We look forward to hearing from you and will get back to you as soon as possible.

Alternatively, you may want to contact directly one of our locations or our holding company.

Locations

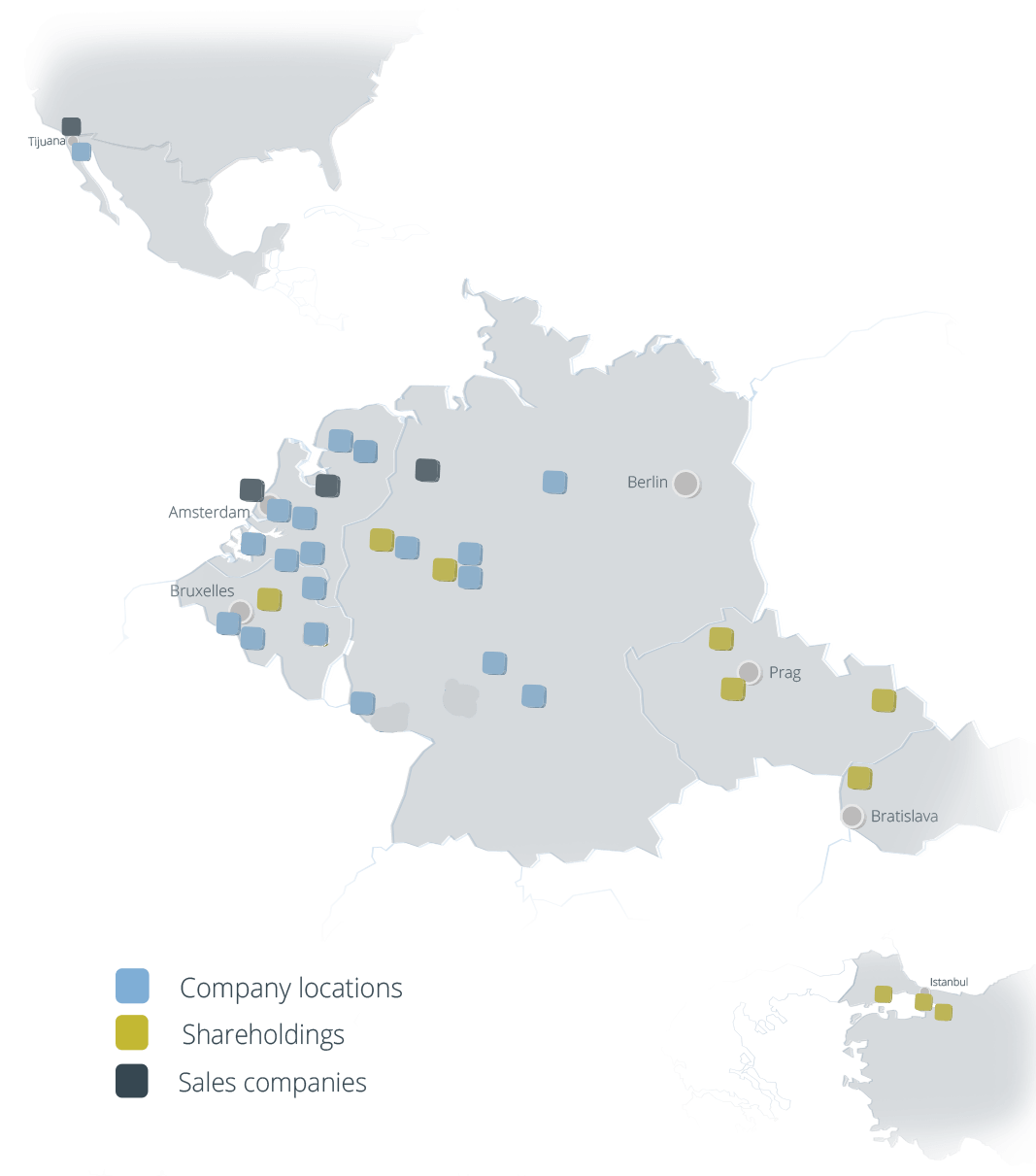

The Coatinc-Network

Slovakia

Netherlands

- Alblasserdam / NL

alblasserdam@coatinc.com - Amsterdam / NL

amsterdam@coatinc.com - Barneveld / NL

nederland@coatinc.com - De Meern / NL

demeern@coatinc.com - Groningen / NL

groningen@coatinc.com - Groningen – Pulverbeschichtung / NL

cgr.verkoop@coatinc.com - Mook / NL

mook@coatinc.com - Mook – PreGa / NL

prega.nl@coatinc.com - Roermond / NL

roermond@coatinc.com - Scherpenzeel / NL

anox@coatinc.com

For enquiries regarding marketing or press matters, please use the following contacts:

Marketing & Press

The Coatinc Company Holding GmbH

Hüttenstraße 45

57223 Kreuztal

Your contact person:

Anna-Maria Ademaj

marketing@coatinc.com

Holding

Headquarter

The Coatinc Company Holding GmbH

Carolinenglückstraße 6-10

44793 Bochum, Germany

Phone: +49 234 52905-0

Fax: +49 234 52905-15

Encyclopedia

White rust

White rust

As the effect of moisture is a fundamental requirement, seasonal influences (autumn and winter, frequent rainfall, mist and undershooting dew points because of low temperatures) play an important role. Also stacking freshly galvanised parts on wet grass, in an unsuitable position or lying flat on top of each other can lead to white rust if moisture is widely present. Even though well intentioned, covering galvanized steel parts, which are stored outside under plastic covers or sheets, can generally cause more harm than good as moist air accumulates under the covers and condensation is an ideal climate for white rust.

Long-term protection from white rust

Also, packaging is only reliable if it is undamaged and no moisture can enter the packaging. Problems with the formation of white rust is particularly likely when dealing with hot-galvanized bulk goods, such as screws or nails, which are stored in damp wooden boxes or open containers out in the open. The formation of white rust has no connection with the galvanization process, nor is it a measure of the quality of galvanization. It is much more an occurrence which is fundamentally dependent on the atmospheric conditions during storage or transportation of the freshly hot-galvanized parts.