Appearance of galvanized steel trade products

Are you an existing customer or do you want to contact us in a different matter? We look forward to hearing from you and will get back to you as soon as possible.

Alternatively, you may want to contact directly one of our locations or our holding company.

Locations

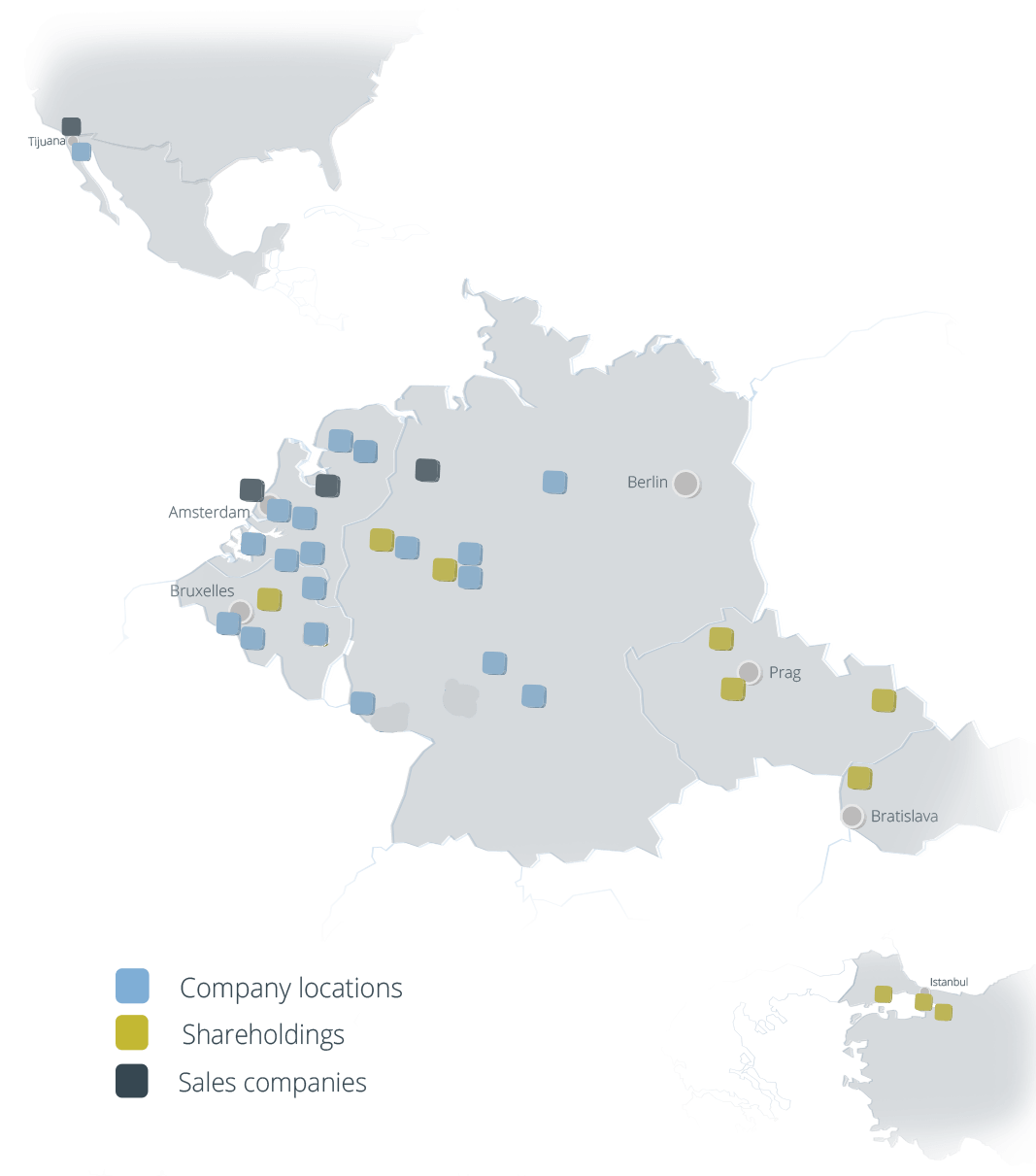

The Coatinc-Network

Slovakia

Netherlands

- Alblasserdam / NL

alblasserdam@coatinc.com - Amsterdam / NL

amsterdam@coatinc.com - Barneveld / NL

nederland@coatinc.com - De Meern / NL

demeern@coatinc.com - Groningen / NL

groningen@coatinc.com - Groningen – Pulverbeschichtung / NL

cgr.verkoop@coatinc.com - Mook / NL

mook@coatinc.com - Mook – PreGa / NL

prega.nl@coatinc.com - Roermond / NL

roermond@coatinc.com - Scherpenzeel / NL

anox@coatinc.com

For enquiries regarding marketing or press matters, please use the following contacts:

Marketing & Press

The Coatinc Company Holding GmbH

Hüttenstraße 45

57223 Kreuztal

Your contact person:

Anna-Maria Ademaj

marketing@coatinc.com

Holding

Headquarter

The Coatinc Company Holding GmbH

Carolinenglückstraße 6-10

44793 Bochum, Germany

Phone: +49 234 52905-0

Fax: +49 234 52905-15

Encyclopedia

Appearance of galvanized steel trade products

Appearance of galvanized steel trade products

What influence do so-called alloy constituents have on the optic of galvanized steel trade products?

The optic of galvanized steel is significantly dependent on silicon and phosphor. If optical and aesthetic demands on the surface finish are high, steel from group 1 (so-called inert range) is recommended. In order to achieve standard corrosion protection, steel from group 3 (sebisty range) is recommended. The two remaining groups lead to not insignificant limitations in the surface finish and also particularly effect the resistance to mechanical demands which is typical for hot-galvanising (mixed crystal – iron-zinc alloy layer).

Where does the orange peel effect on galvanised steel trade products come from?

What effect does the material or wall width have on the appearance? The greater the material and/or wall width, the longer the temperature of the galvanising bath is stored in the workpiece. The components therefore continue to alloy chemically and physically which defines the visual appearance. The less material used and/or the thickness of the selected steel (here in particular for class 1, inert range) the more possible it is to produce a more sophisticated surface finish. These are normally materials originating from the quality range S235.

How does the appearance change on bright steel?

In addition to the alloy constituents silicon and phosphor, which fundamentally define the appearance, phosphates, which occur as aid in drawn materials, also play a substantial role. Phosphates normally generate the so-called orange peel effect which often occurs particularly in hollow profiles.

Additional information: the above-mentioned problem can be deactivated by using aluminium killed materials. However these materials are normally uneconomical.