Surfaces

Are you an existing customer or do you want to contact us in a different matter? We look forward to hearing from you and will get back to you as soon as possible.

Alternatively, you may want to contact directly one of our locations or our holding company.

Locations

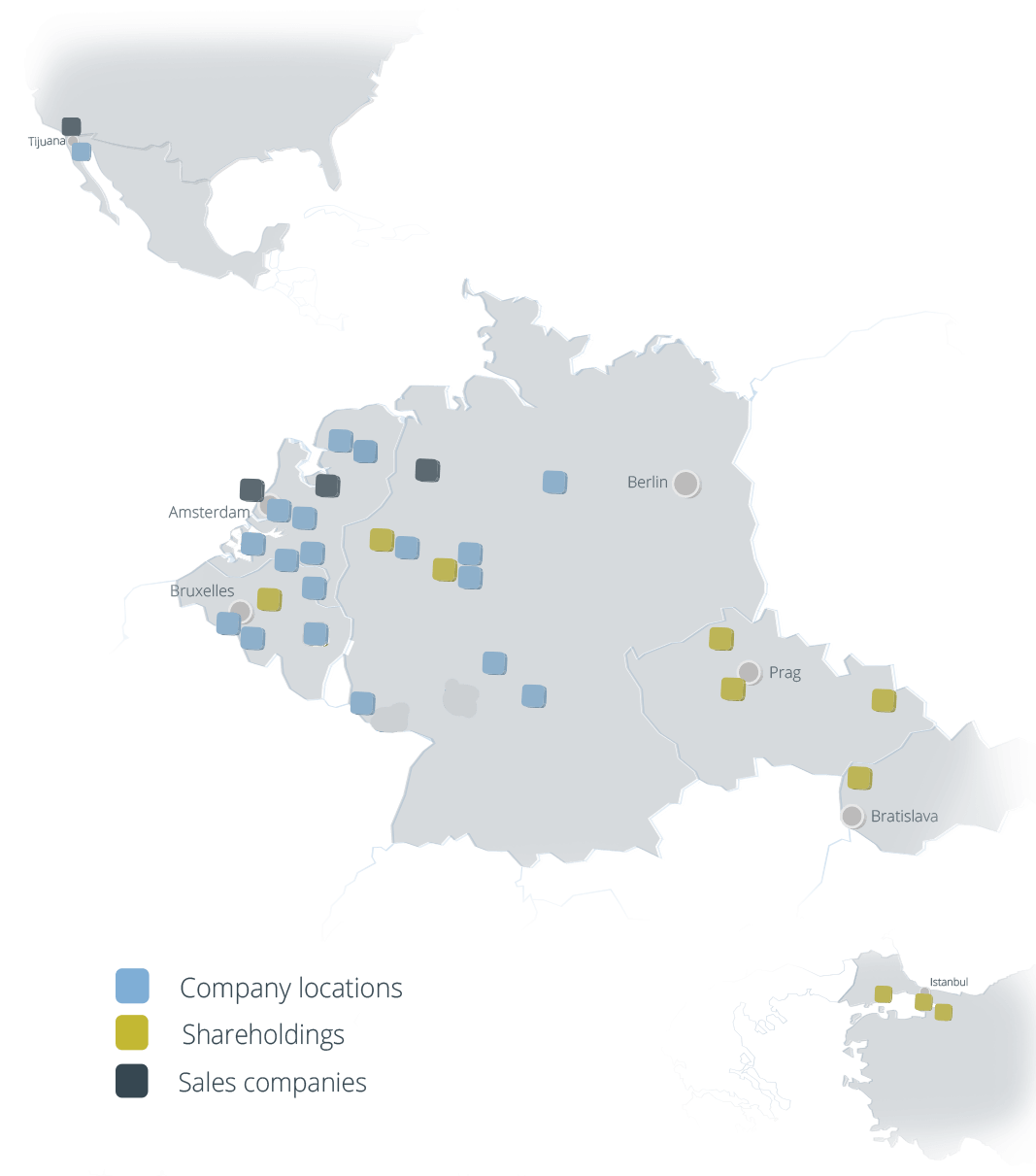

The Coatinc-Network

Slovakia

Netherlands

- Alblasserdam / NL

alblasserdam@coatinc.com - Amsterdam / NL

amsterdam@coatinc.com - Barneveld / NL

nederland@coatinc.com - De Meern / NL

demeern@coatinc.com - Groningen / NL

groningen@coatinc.com - Groningen – Pulverbeschichtung / NL

cgr.verkoop@coatinc.com - Mook / NL

mook@coatinc.com - Mook – PreGa / NL

prega.nl@coatinc.com - Roermond / NL

roermond@coatinc.com - Scherpenzeel / NL

anox@coatinc.com

For enquiries regarding marketing or press matters, please use the following contacts:

Marketing & Press

The Coatinc Company Holding GmbH

Hüttenstraße 45

57223 Kreuztal

Your contact person:

Anna-Maria Ademaj

marketing@coatinc.com

Holding

Headquarter

The Coatinc Company Holding GmbH

Carolinenglückstraße 6-10

44793 Bochum, Germany

Phone: +49 234 52905-0

Fax: +49 234 52905-15

Encyclopedia

Surfaces

Surfaces

Make materials useful – with surface treatment

Materials have very different physical, chemical and tribological properties. Physical properties are fundamentally nuclear physical and electrical properties such as thermal conductivity or also ferromagnatical and optical properties such as thermal expansion … Chemical and tribological properties are, for example electrochemical corrosion, scaling, crevice corrosion caused by tension, material failure, boundary areas and adhesion of surfaces … An understanding of the formation of coating and coating properties requires detailed knowledge: in particular of the substrate (material), the material which forms the coat, the defined purpose of the coating and the type of bonding conditions and the sequence of the individual procedural components in the area near the surface.

The task and aim of surface technology

Every surface is different and acts differently accordingly. However in order for it to be able to fulfil the requirements placed on it, for example wear resistance and corrosion resistance, strength, anti-friction properties or optic, it is important to change it whenever possible, according to precisely defined properties. The aim is to generate a new surface behaviour for specific purposes!

The procedure defines the result

The procedures of surface technology have both technological similarities as well as clear technological differences. Differences arise in the properties of the coats and their physical-chemical behaviour towards the substrate (material) surfaces. DIN EN 8580 divides the procedures into the physical-chemical procedures in the coat-forming material. In order to achieve the specified goals ‘defined surface properties’, the substrate surfaces must be changed in their structure.